DISTRIBUTION CENTRES

The DC’s in this website vary in size from 3000 tons product till 60000 ton product. There is also a subdivision to product-specific DC’s for example only potatoes, and multi product DC’s. In this part we present fully worked examples.

This section of the site explains the main components of all the different DC’s. Each subject as: DC total, Processing and Storage is as much as possible shown in the same way and order. With the use of animations, 3D and 2D drawings the following be explained for each part: DC Total part shows the whole distribution process with product flow. Processing lines part displays into detail the processing possibilities of various products with the processing capacity. Storage part shows the different storage systems by product with the required equipment.

DISTRIBUTION CENTRES

The DC’s in this website vary in size from 3000 tons product till 60000 ton product. There is also a subdivision to product-specific DC’s for example only potatoes, and multi product DC’s. In this part we present fully worked examples.

The DC’s in this website vary in size from 3000 tons product till 60000 ton product. There is also a subdivision to product-specific DC’s for example only potatoes, and multi product DC’s.

This section of the site explains the main components of all the different DC’s. Each subject as: DC total, Processing and Storage is as much as possible shown in the same way and order. With the use of animations, 3D and 2D drawings the following be explained for each part: DC Total part shows the whole distribution process with product flow. Processing lines part displays into detail the processing possibilities of various products with the processing capacity. Storage part shows the different storage systems by product with the required equipment.

Animations

- A full range of Distribution Centres from 3.000 to 60.000 tons of storage

- Product specifics Distribution Centres

- Multi product Distribution Centres

- A Distribution Centre will full processing lines when needed

- We can provide interested parties with a comprehensive proposal in a quickly and professional manner. With our proposal subsidies, NGO support programs and bank loans are taken into account.

Animations

- A full range of Distribution Centres from 3.000 to 60.000 tons of storage

- Product specifics Distribution Centres

- Multi product Distribution Centres

- A Distribution Centre will full processing lines when needed

- We can provide interested parties with a comprehensive proposal in a quickly and professional manner. With our proposal subsidies, NGO support programs and bank loans are taken into account.

Processing lines

Allround processing lines for: potatoes, carrots, onions, set onions, red beet, turnips, parsnips, celeriac, swedes and brussels sprouts with capacities from 2 up to 50 tons per hour.

- All machines from one manufacturer

- Transparancy of costs

- One service point

- Machines are compatible with each other

- Compatible with all brands of weighing and packaging machines

- Possibility to extend the line easily

- Tailer-made installation on demand

- Complete stainless steel on demand

Processing lines

Allround processing lines for: potatoes, carrots, onions, set onions, red beet, turnips, parsnips, celeriac, swedes and brussels sprouts with capacities from 2 up to 50 tons per hour.

- All machines from one manufacturer

- Transparancy of costs

- One service point

- Machines are compatible with each other

- Compatible with all brands of weighing and packaging machines

- Possibility to extend the line easily

- Tailer-made installation on demand

- Complete stainless steel on demand

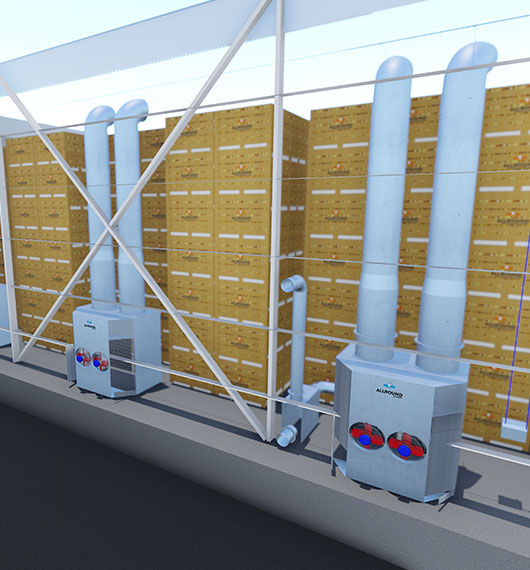

Storage

Allround storage solutions specifically for each situation.

The reasons to store:

- The distribution centre can profit from market price developments during harvesting season.

- By creating the optimal storage conditions disease and sprouting is prevented, and the product quality is maintained.

- Weight loss is reduced to a minimum since the product is sold mostly by weight, weight loss results in fewer profit.

- The storage facility will act as a buffer for the processing line especially for industrial factories.

- Reducing the environmental footprint transporting produce over a large distance is quite heavy on the environment.

Storage

Allround storage solutions specifically for each situation.

The reasons to store:

- The distribution centre can profit from market price developments during harvesting season.

- By creating the optimal storage conditions disease and sprouting is prevented, and the product quality is maintained.

- Weight loss is reduced to a minimum since the product is sold mostly by weight, weight loss results in fewer profit.

- The storage facility will act as a buffer for the processing line especially for industrial factories.

- Reducing the environmental footprint transporting produce over a large distance is quite heavy on the environment.

Virtual tour

Virtual Reality (VR) is the use of computer technology to create a simulated environment. Unlike traditional user interfaces, VR places the user inside an experience. Instead of viewing a screen in front of them, users are immersed and able to interact with 3D worlds.