Project Description

Visit our website with a bigger device for more information

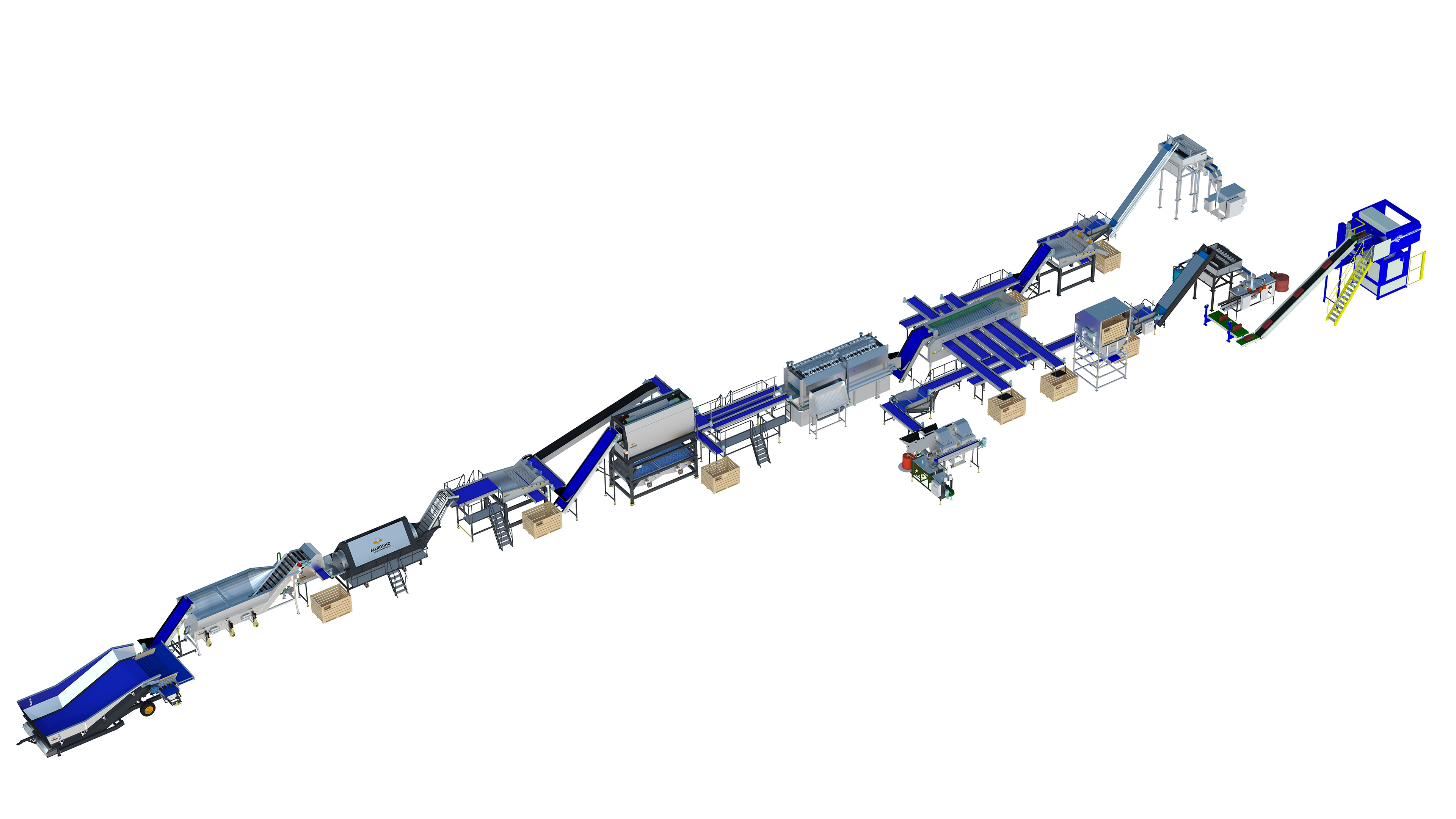

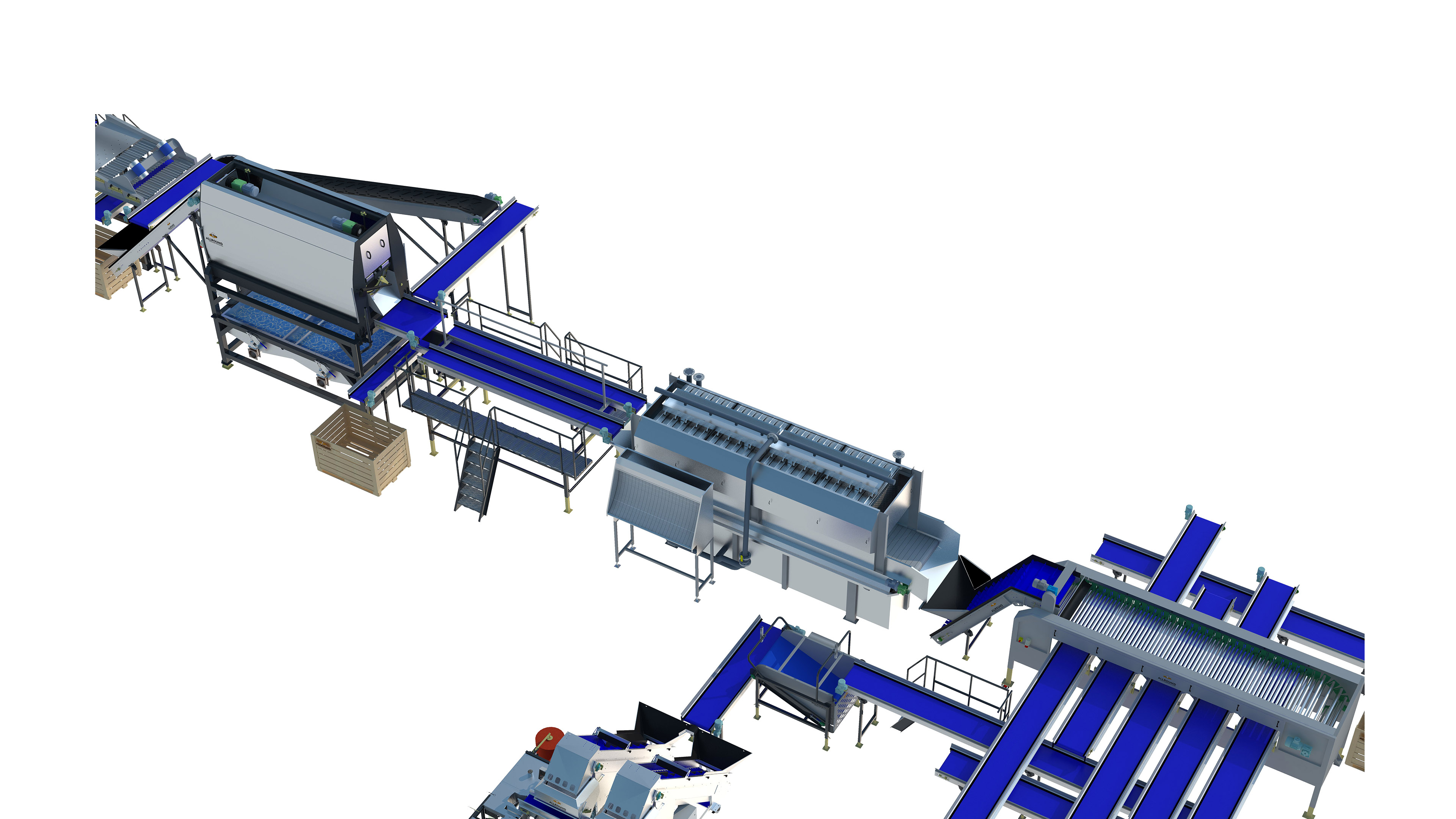

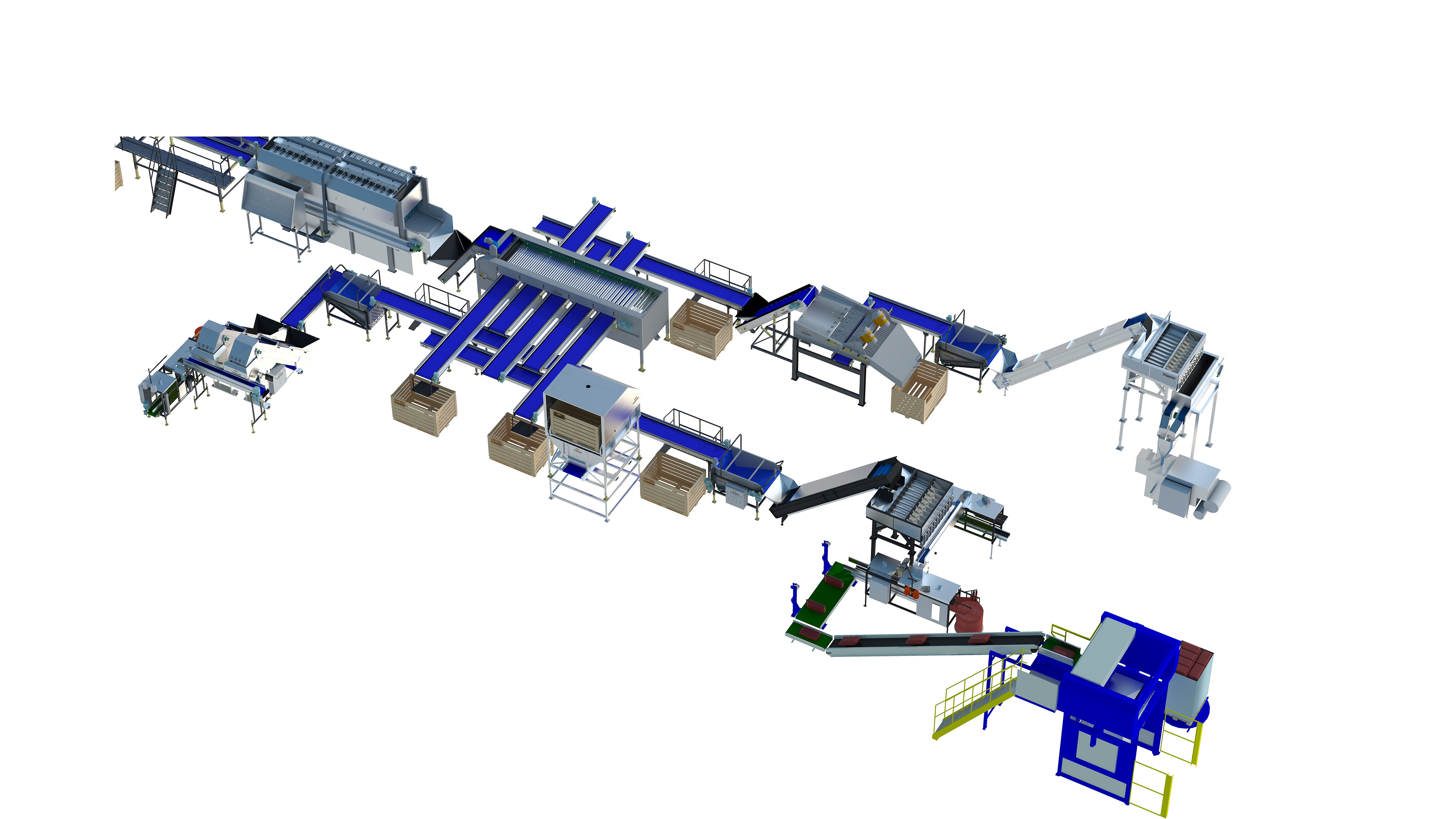

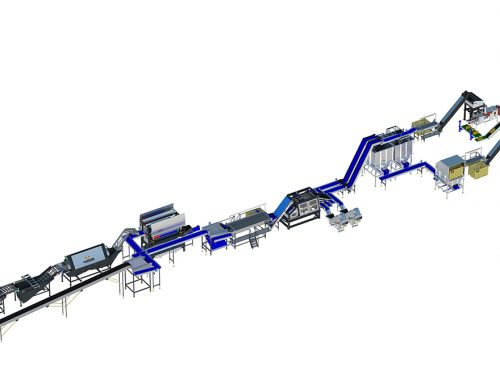

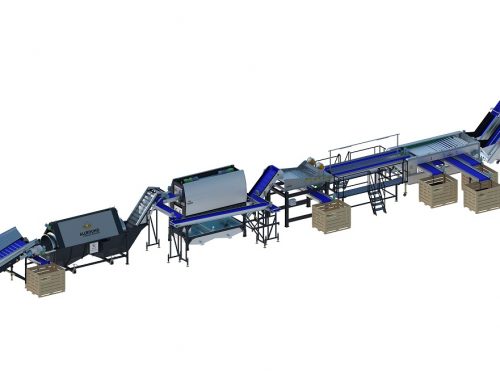

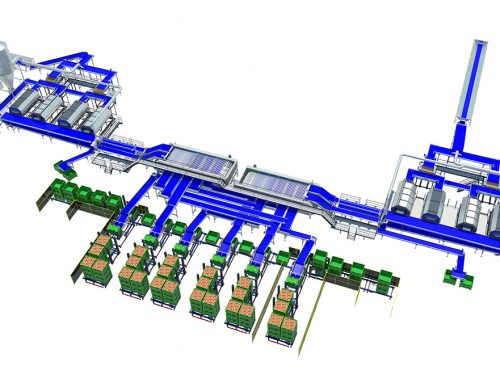

CARROT PROCESSING LINE 500 SERIES

This line is designed to wash carrots. The principle is that a product is placed in the hopper, which then slowly fills the elevator. This is line include the washing machine U 500. The U 500 are designed to operate with a water basin. In this water basin, the water used in the machine is recirculated to be used again.

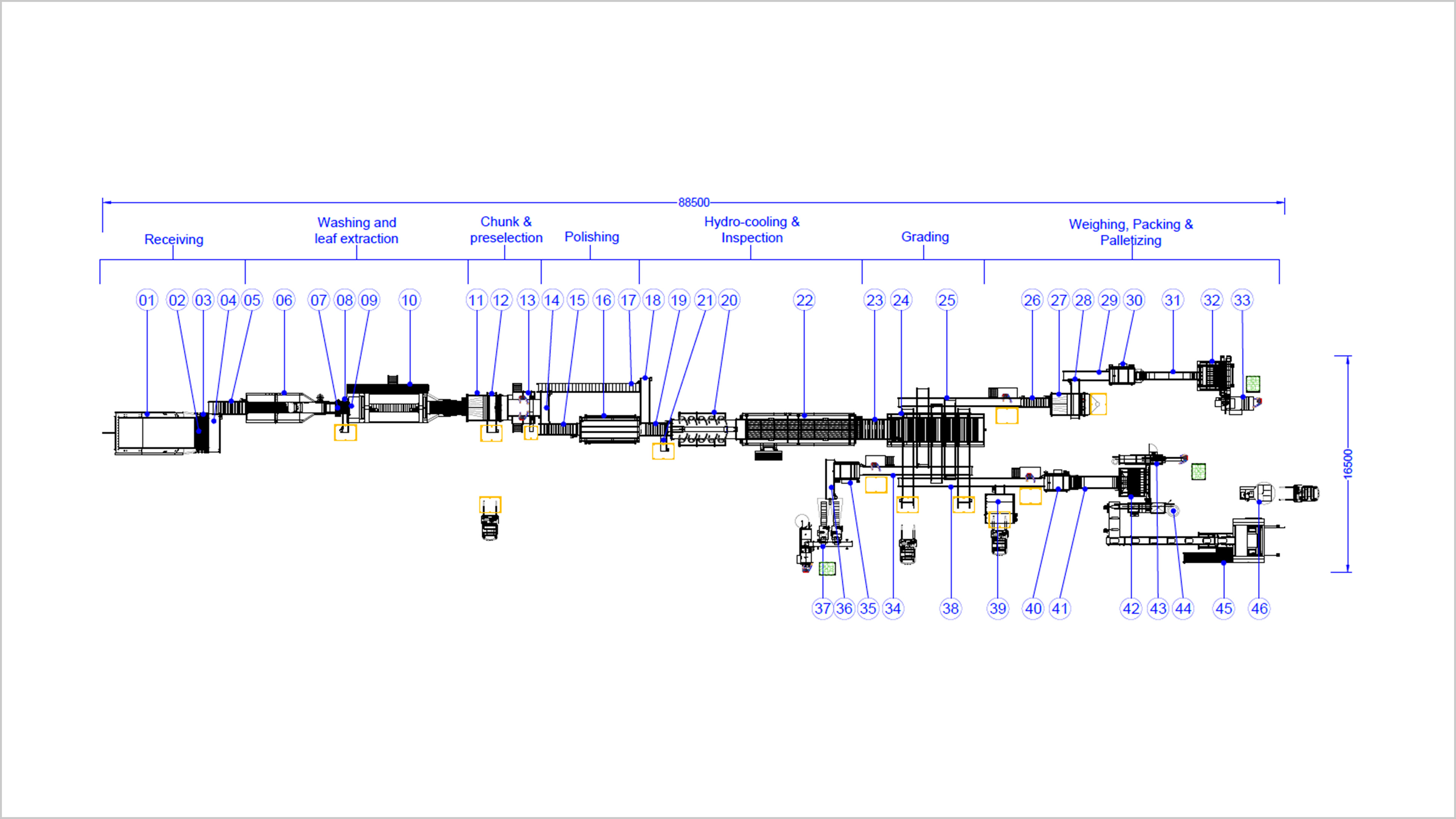

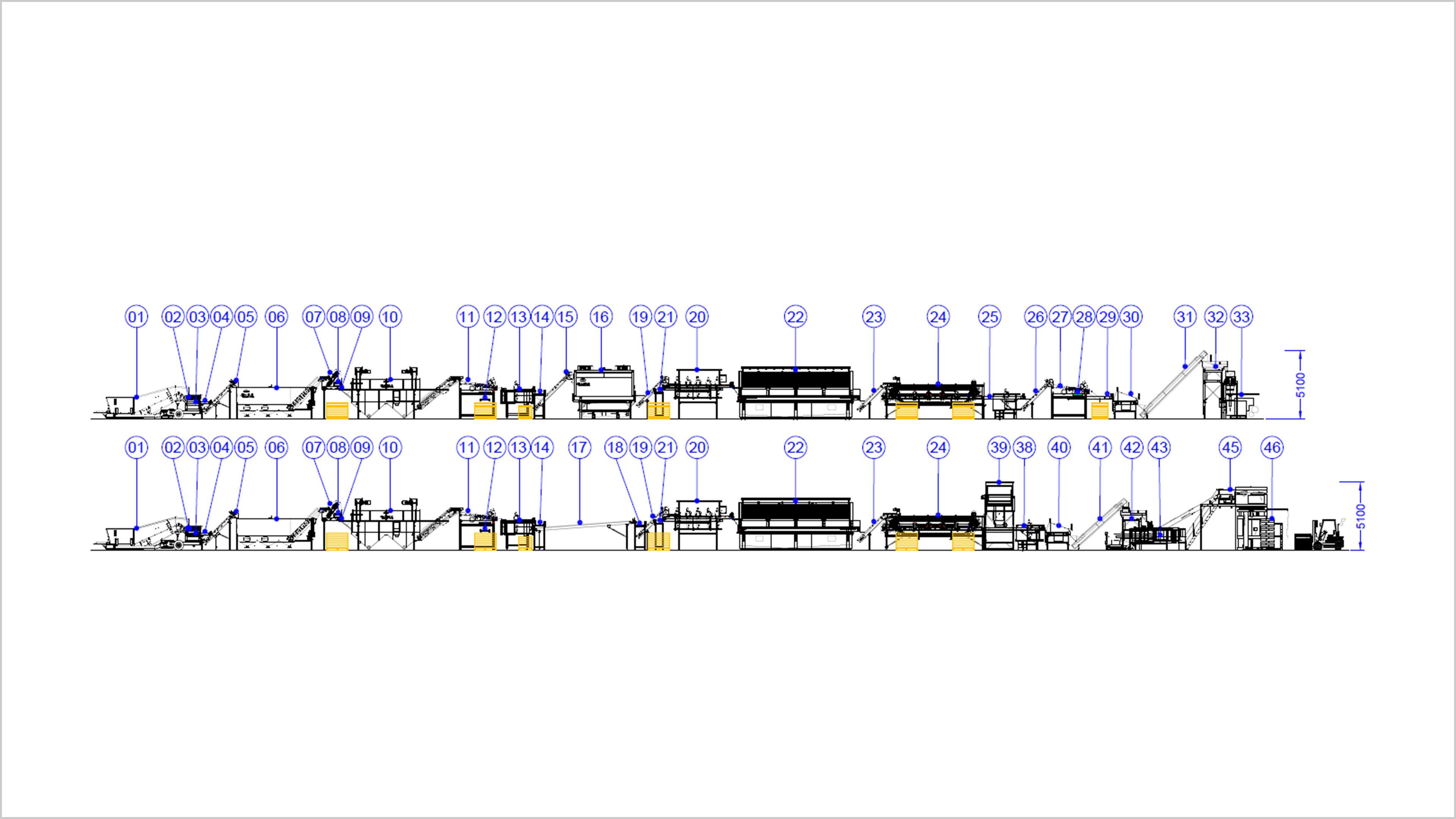

Machine

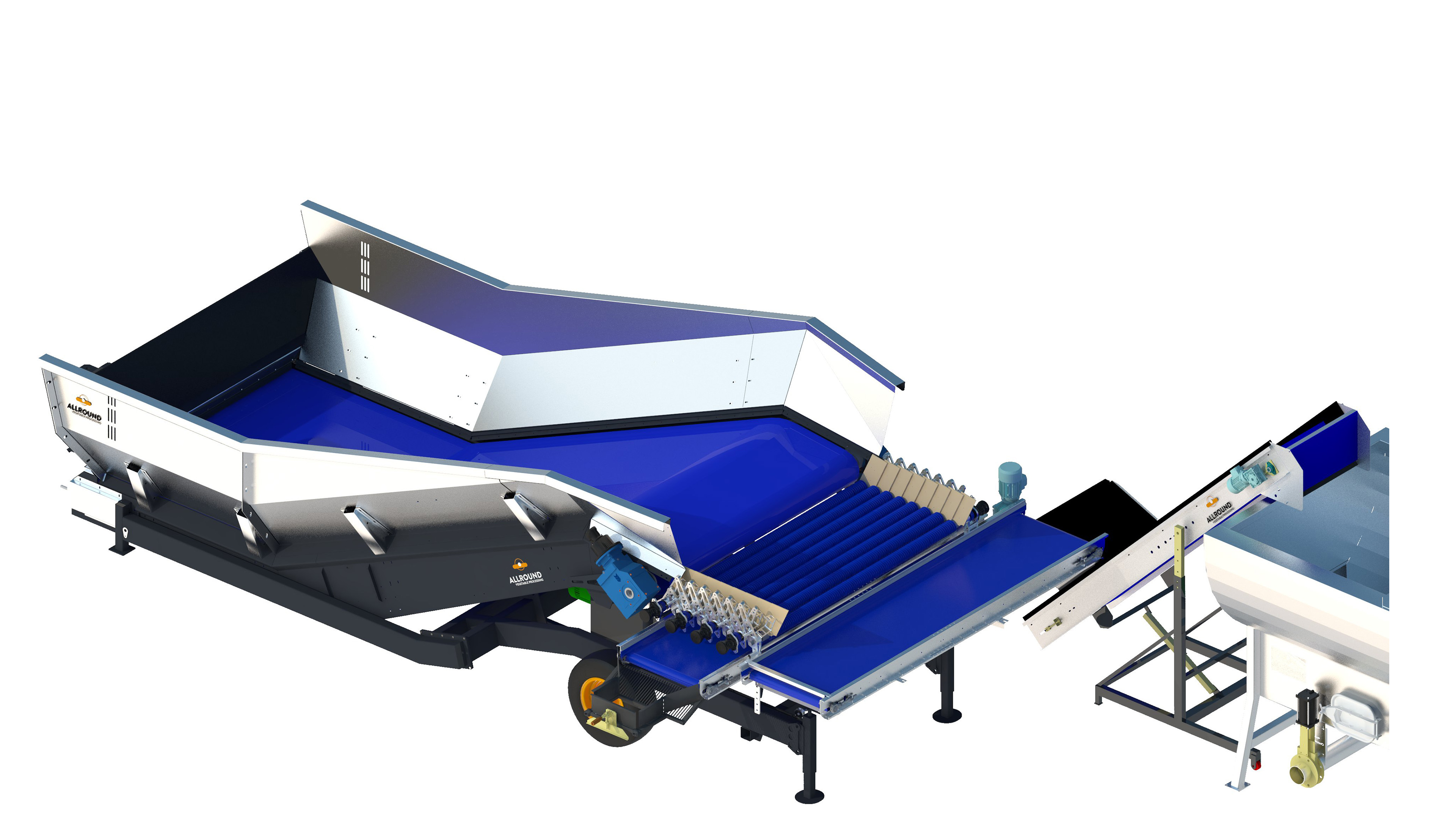

1. Receiving Hopper

2. Spiral roller set

3. Waste belt

4. Product belt

5. Elevator

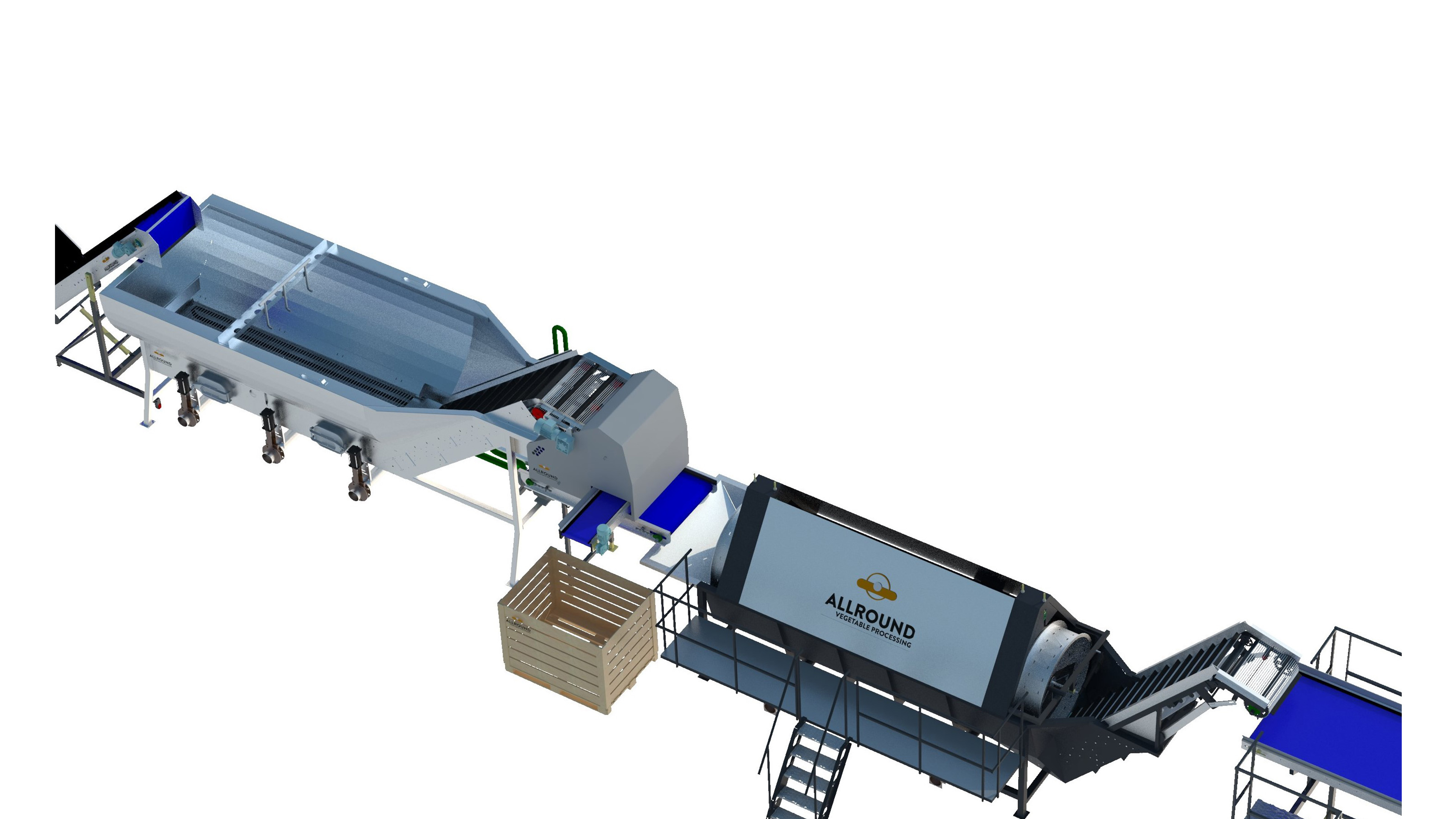

6. Wet Hopper

7. Leaf separator

8. Waste belt

9. Product belt

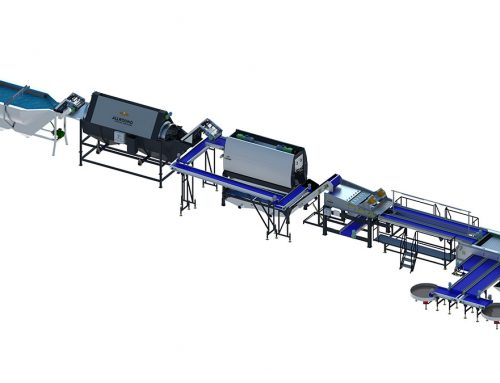

10. Washing machine

11. Chunk grader

12. Waste belt

13. Selection belt

14. Reversible belt

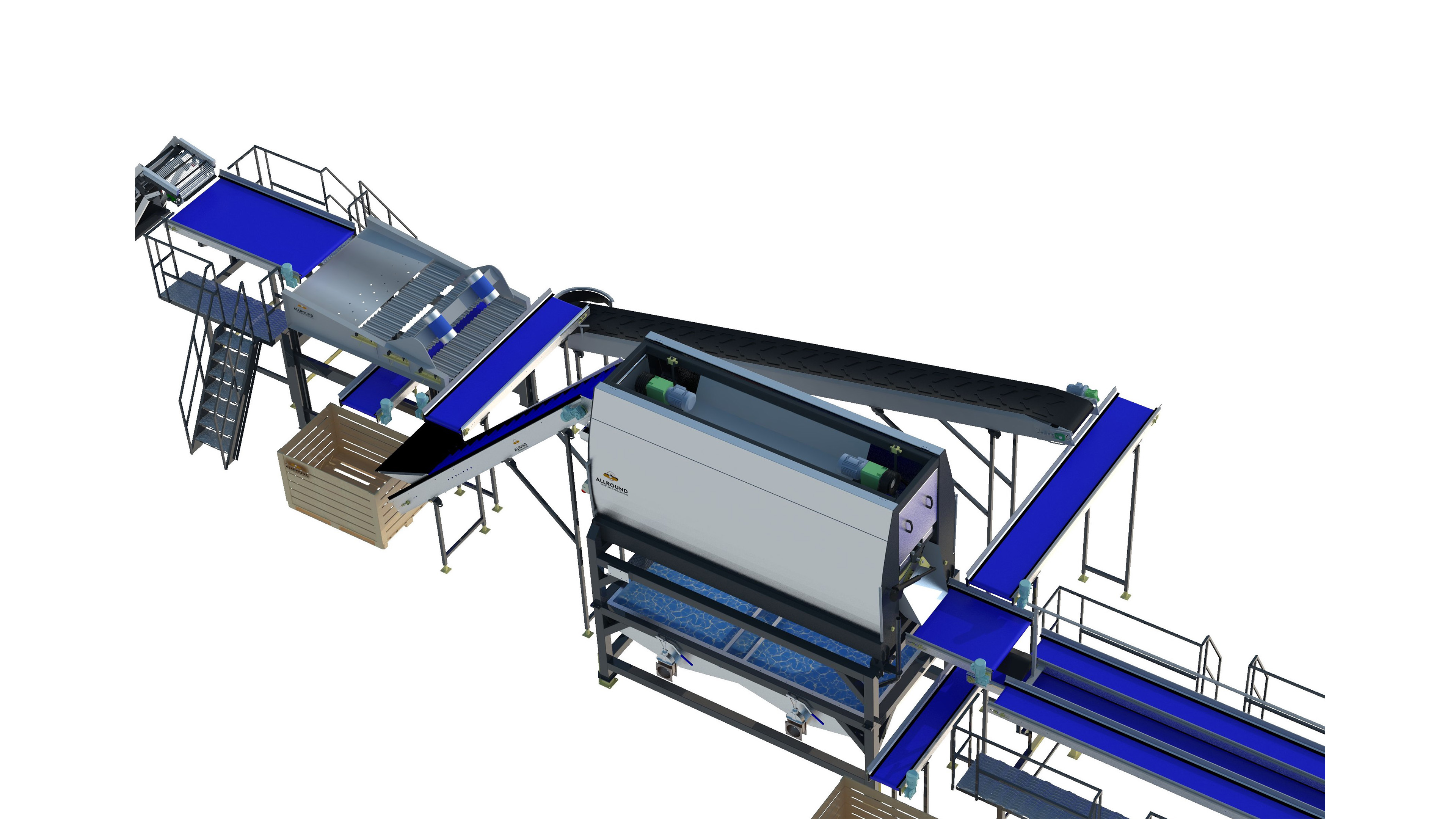

15. Elevator

16. Polisher

17. Bypass belt

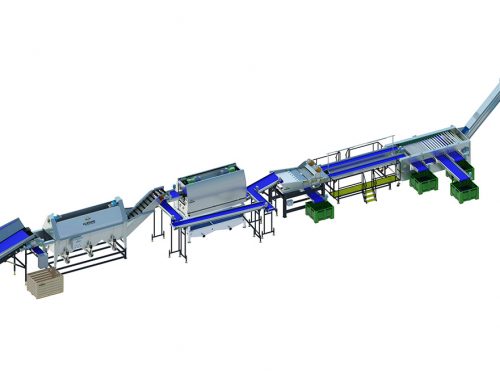

18. Collection belt

19. Elevator

20. Double Inspection belt

21. Waste belt

22. Hydro cooler

23. Swan neck Elevator

24. Radial grader

25. Transport belt

26. Elevator

27. Length grader

28. Product belt

29. Product belt

30. Even flow hopper

31. Elevator

32. Multihead weigher

33. Vertical fill baggar

34. Product belt

35. Even flow hopper

36. Product belt

37. Automatic weghing, bagging & Stiching

38. Product belt

39. Storage cum box tipper(SHB)

40. Even flow hopper

41. Elevator

42. Multihead weigher

43. Roll stock bagger

44. Foil bagger

45. Palletizer

46. Stand alone wrapping machine

Type

ARH 240-600

VS 240-8

TB 300-80

TB 300-60

EL 325-80

J4T

LS 80-110

TC 250-40

TC 150-80

U 500

L 180-2

TB 250-60

TB 250-120

TB 250-60

EL 375-80

TD 350-18

TCC 775-60

TB 350-60

EL 300-80

D 500-50++

TB 200-60

HC 200 KW

ELK 275-100-150

R 170-70-5 St.80

TC 950-60

EL 300-60

L 150-2

TB 250-60

TB 350-60

EF 100-0,7m3

EL 650-60

M12 CA

VFFS

TC 850-60

EF 100-0,7m3

TB 300-60

AWBS-25

TC 1100-60

SHB 160

EF 100-0,7m3

EL 500-60

M10 CA

RSB-M

—

VPM 7

Brand

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

MANTER

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

ALLROUND

MANTER

MANTER

MANTER

VERBRUGGEN

ALLROUND

2D Drawings with machinery list Download here