Project Description

Visit our website with a bigger device for more information

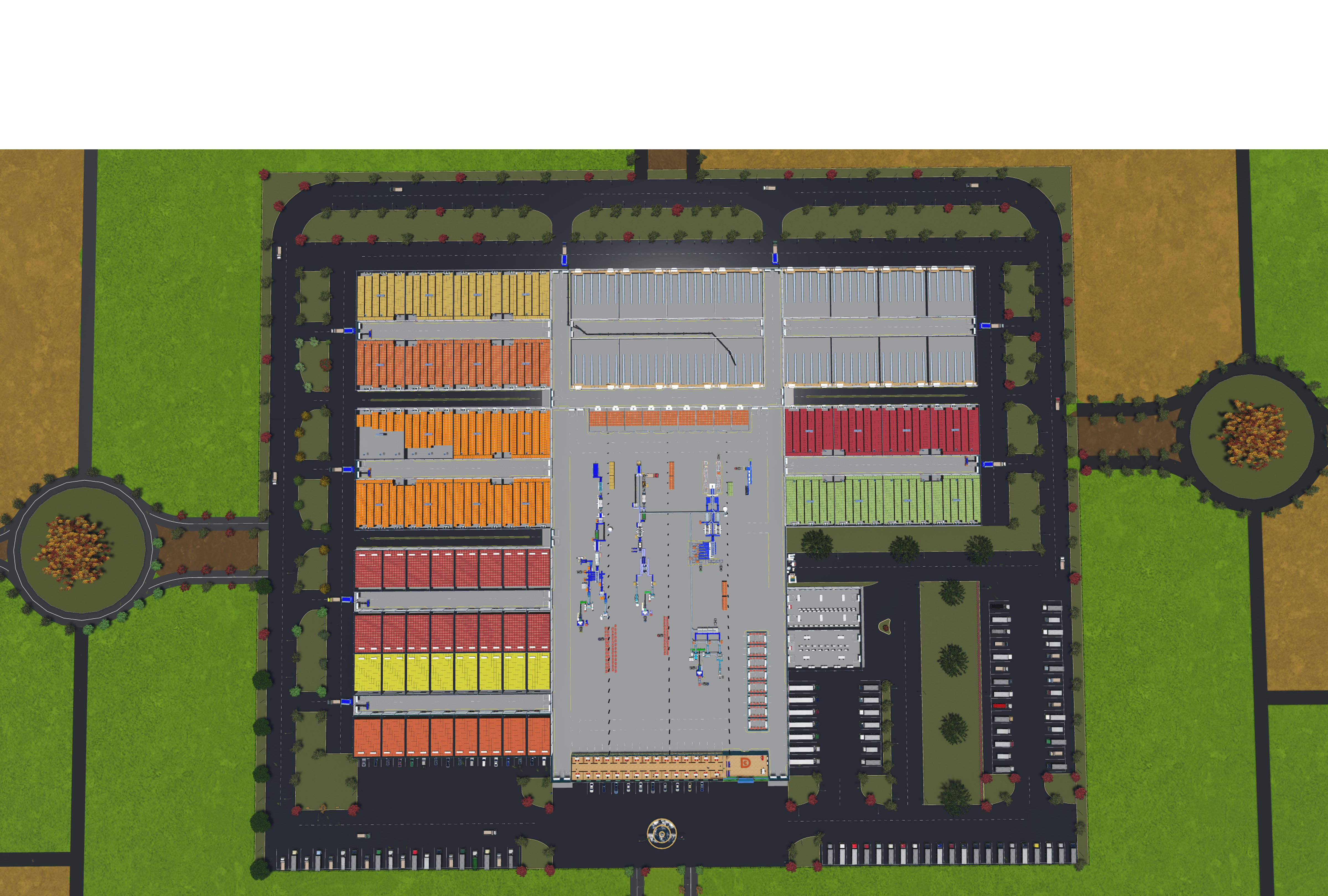

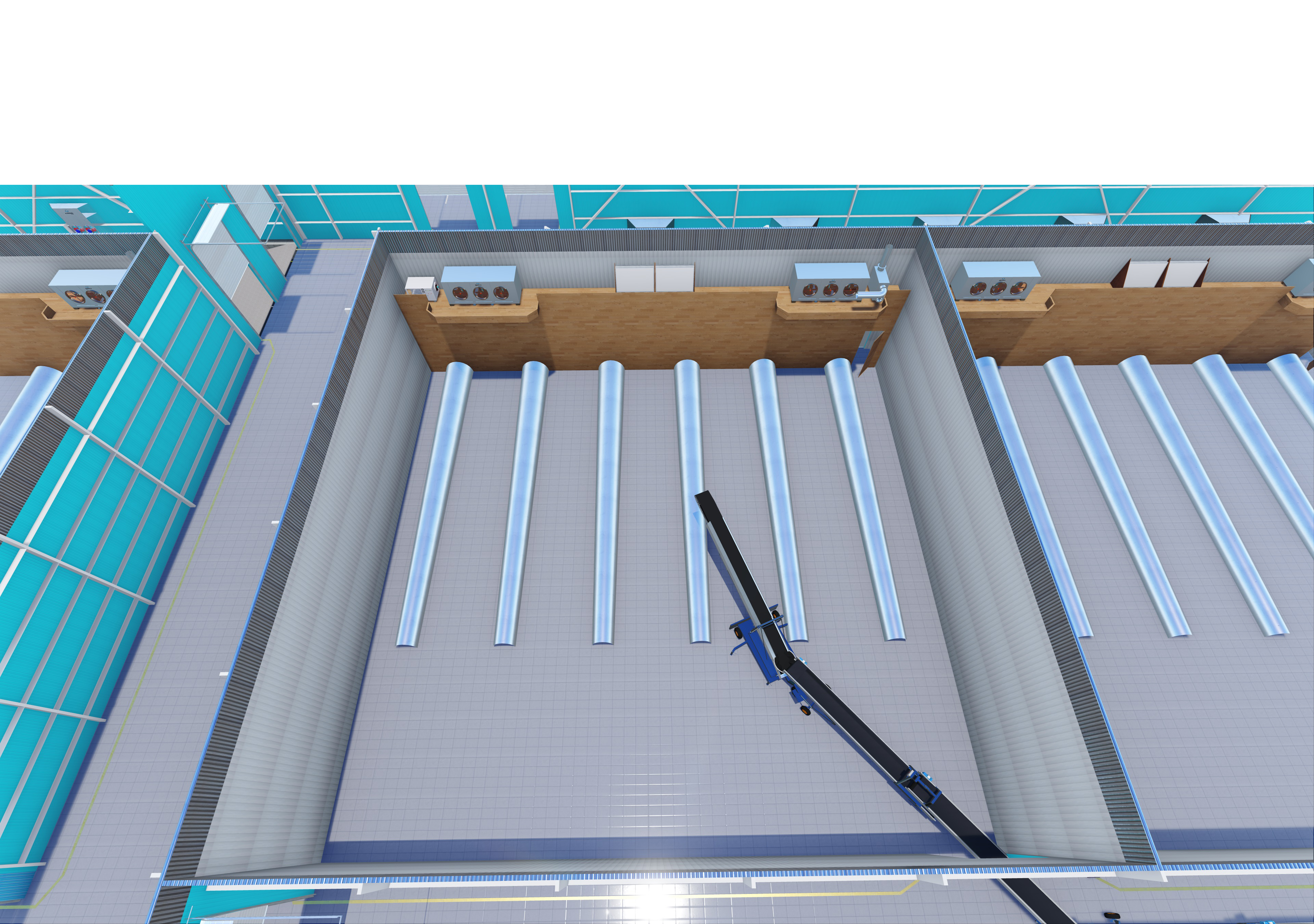

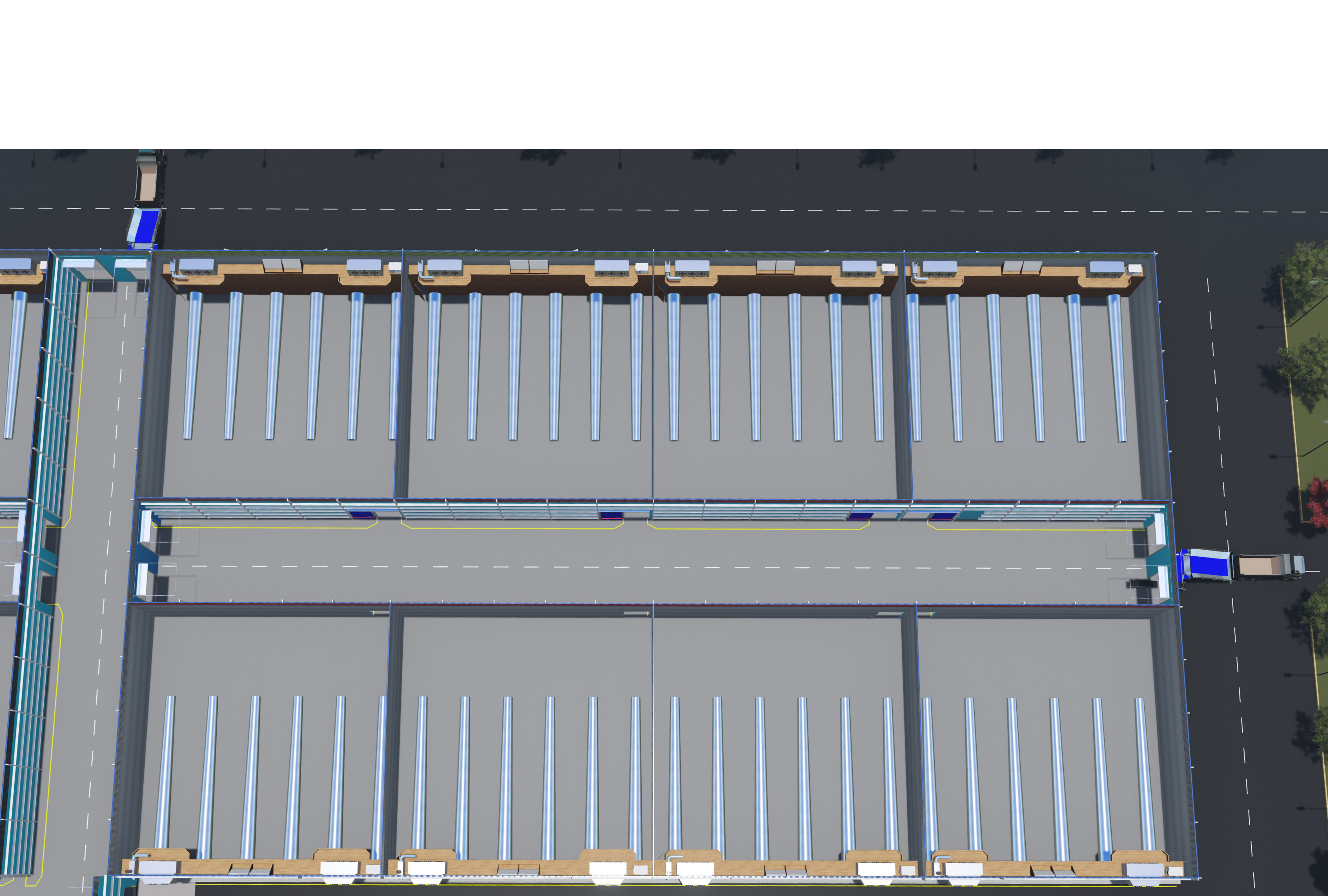

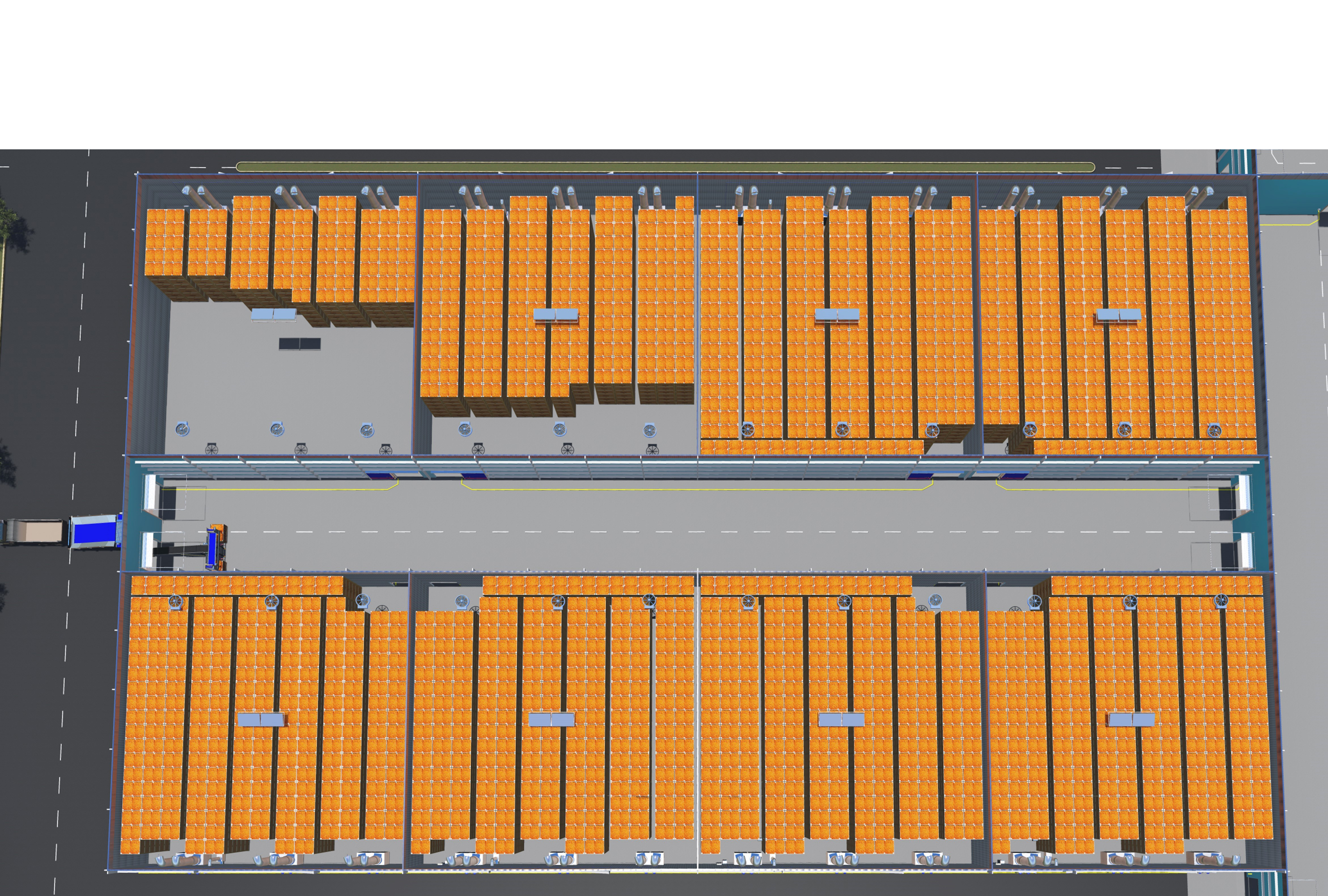

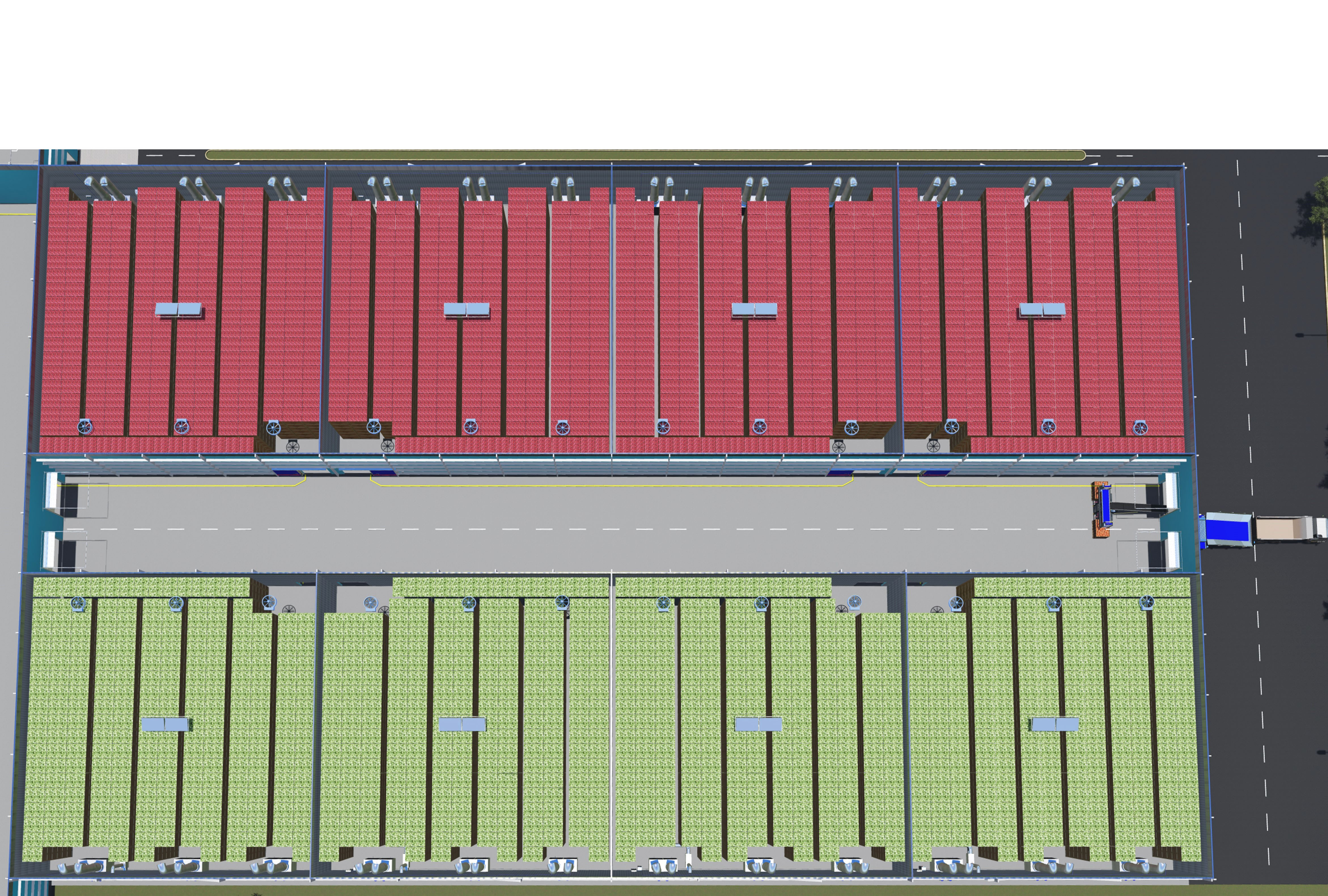

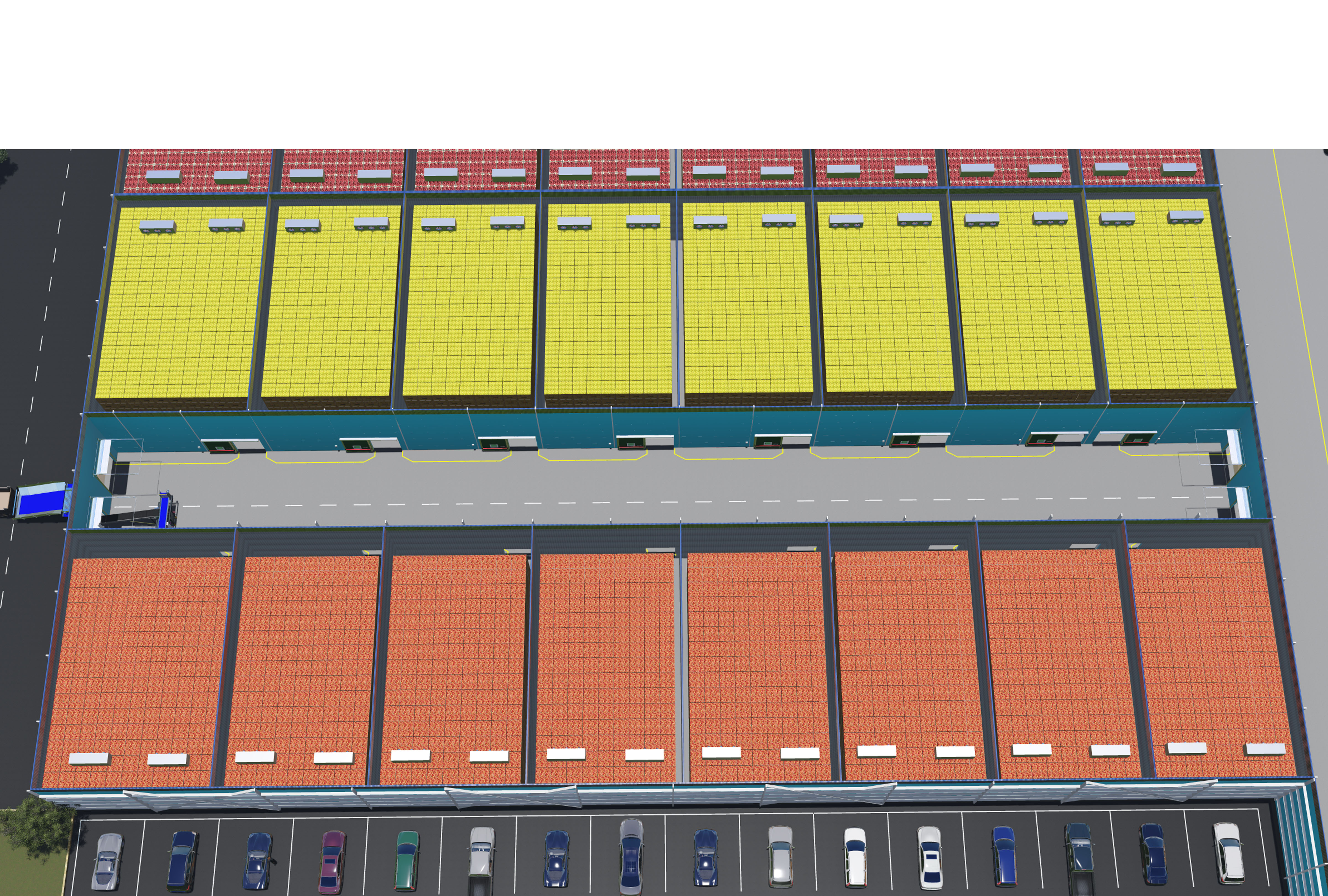

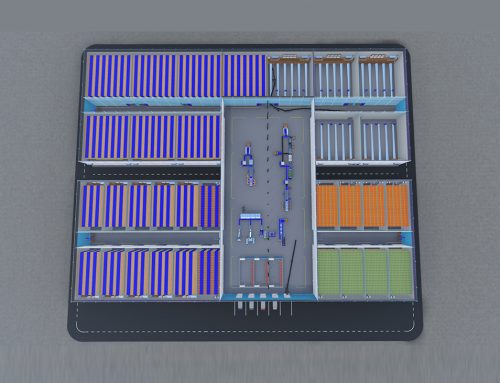

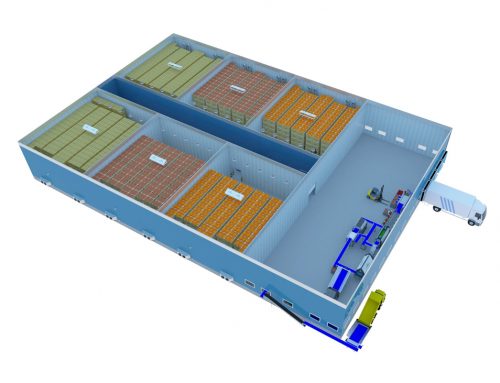

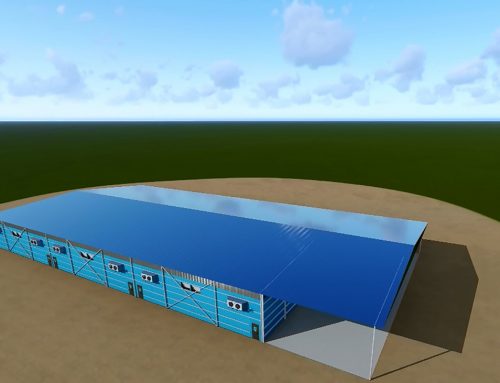

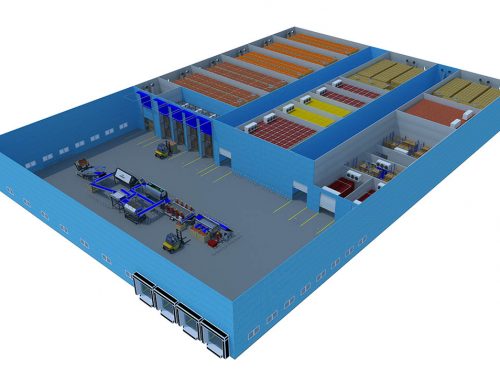

Animation Multi product Distribution Centre of 60,000 tons storage

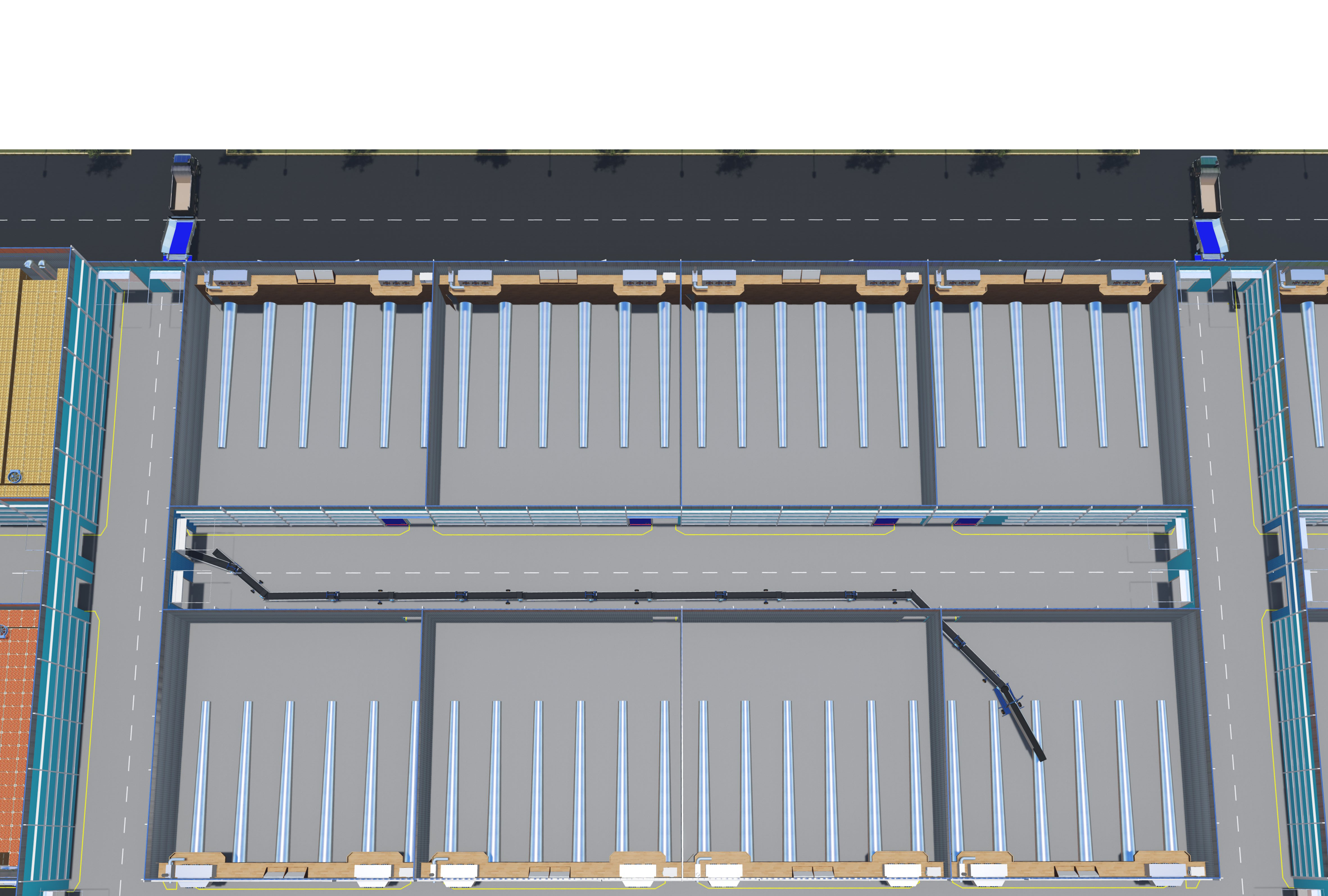

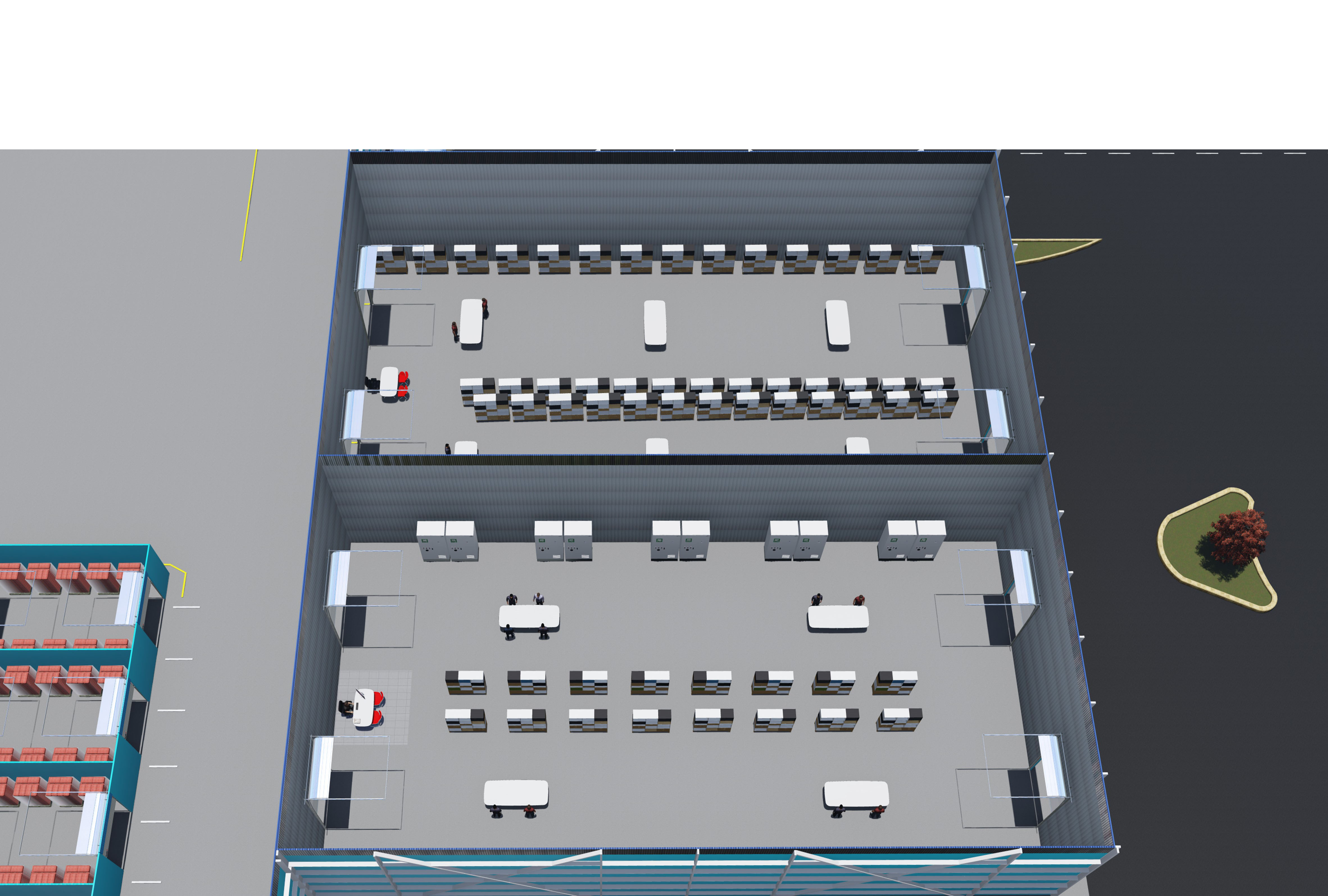

A distribution centre in the middle of a production area next to a highway. With a well-organized dispatch and supply department.

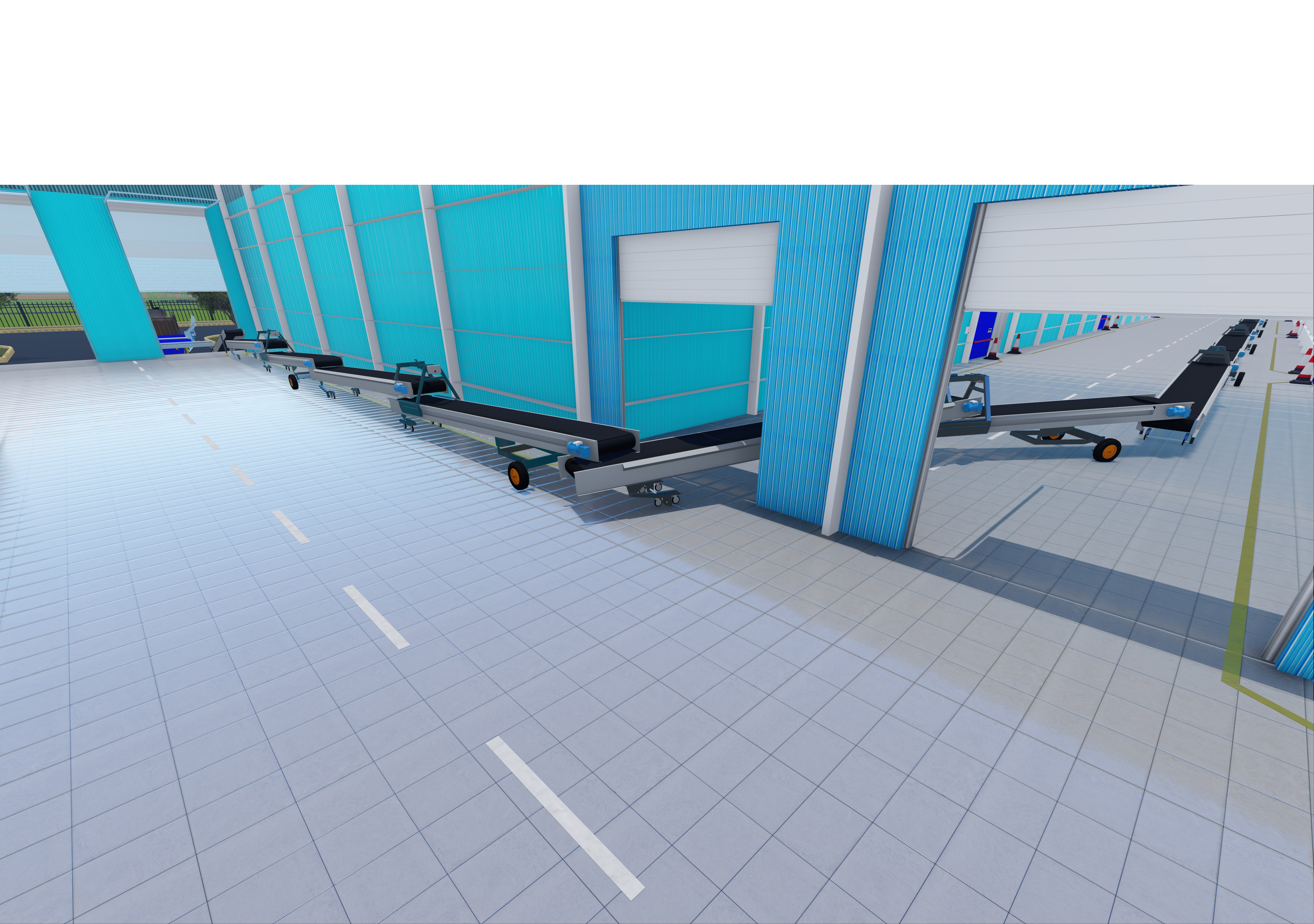

- Infeed of product from field.

- Distance from cold store to processing lines as short as possible.

- Packaging machines all on one line at the end of the processing lines.

- This enables the most efficient logistic product flow of ready product.

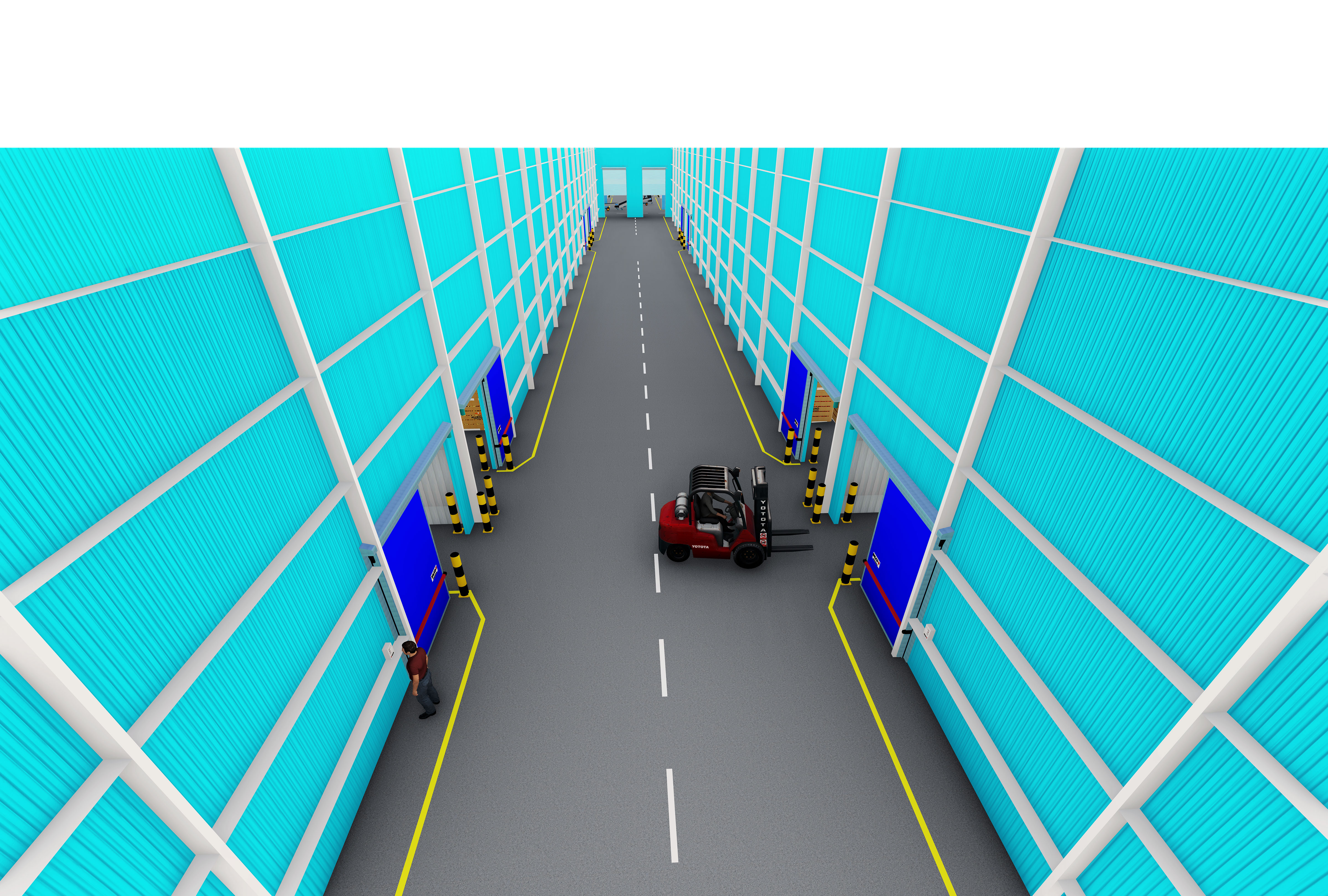

- Centralized dispatch of ready products from condioned rooms.

- Possible to place fruit packaging and grading lines.

- Office block in front of the building.

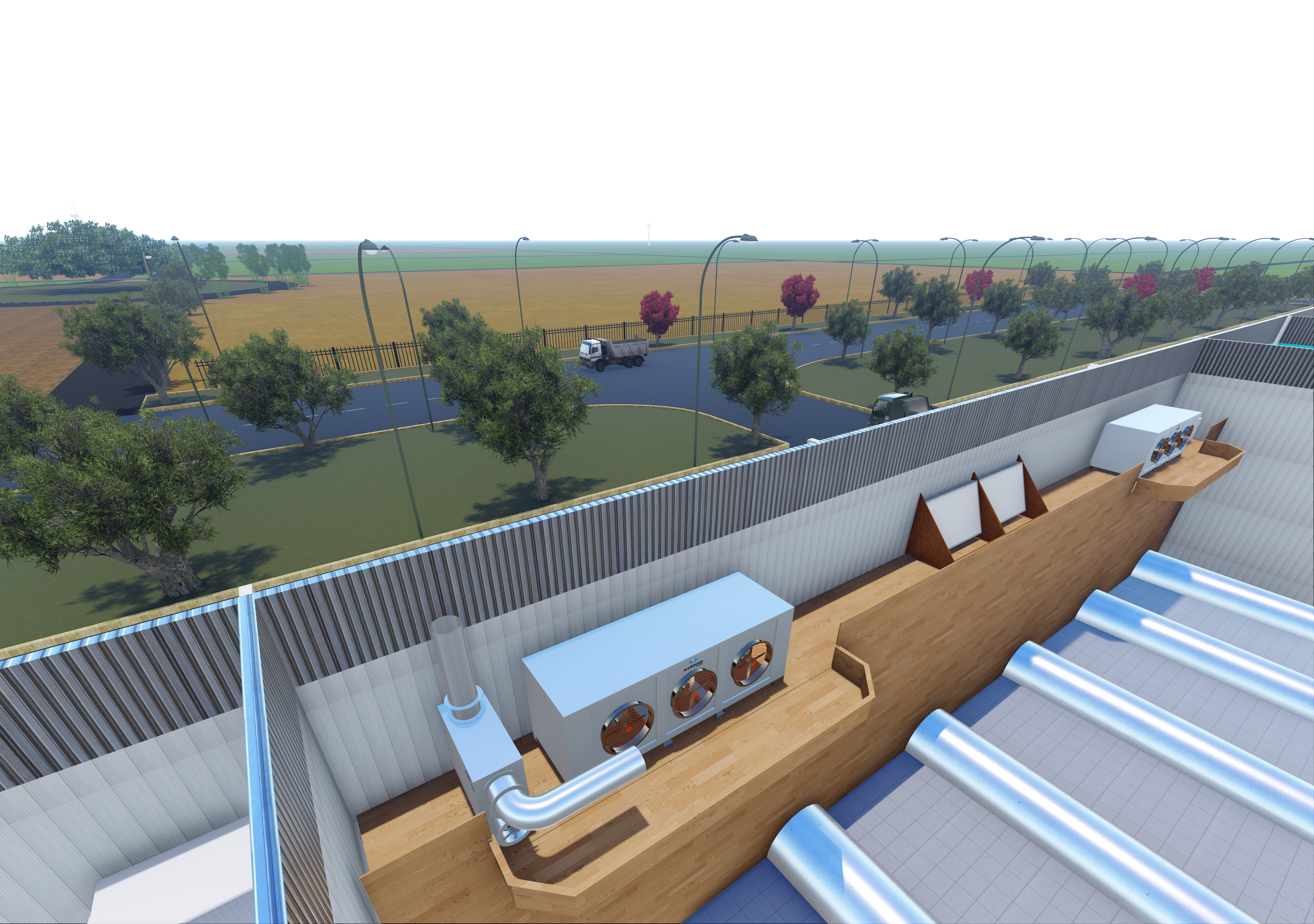

- Solar panels on roof and windmills in the fields.

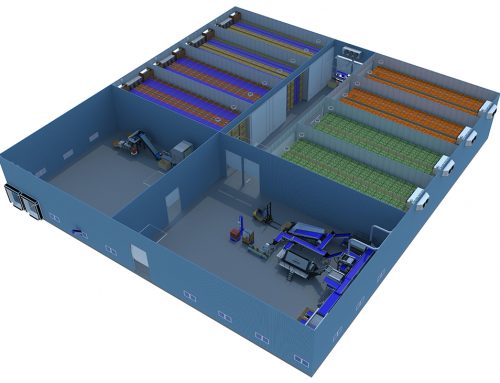

- Reconditioning rooms during proces. for examples onions to be topped at 21 degrees and to be packed at 12 degrees.

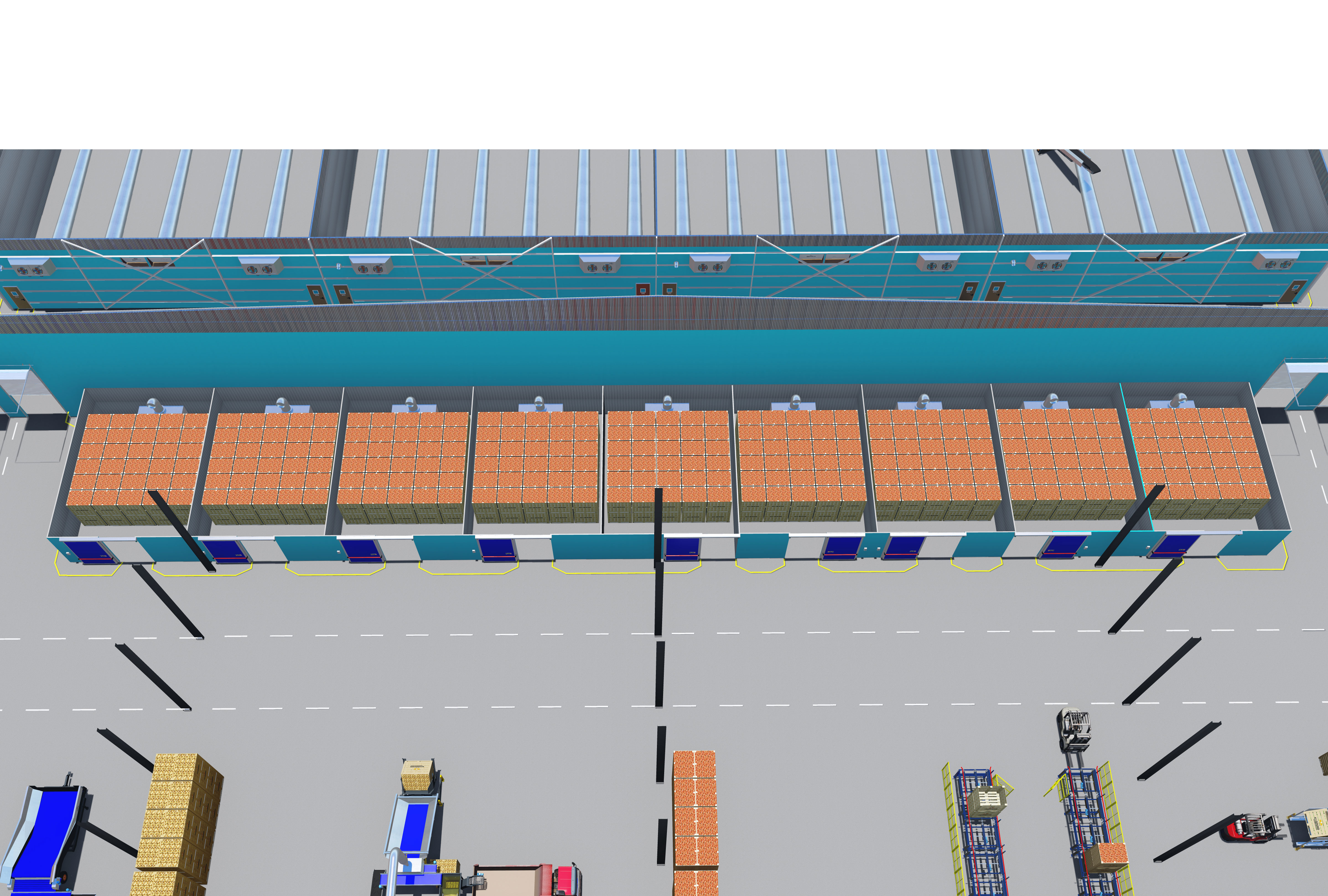

- Conditioning rooms at dispatch. To keep product as fresh as possible.

- Industrial potatoes bulk

- Table potatoes bulk

- Table potatoes boxes

- Seed potatoes boxes

- Carrot boxes

- Onion bulk

- Onion boxes

- Red beet bulk

- Cabbage boxes

- Fruit boxes

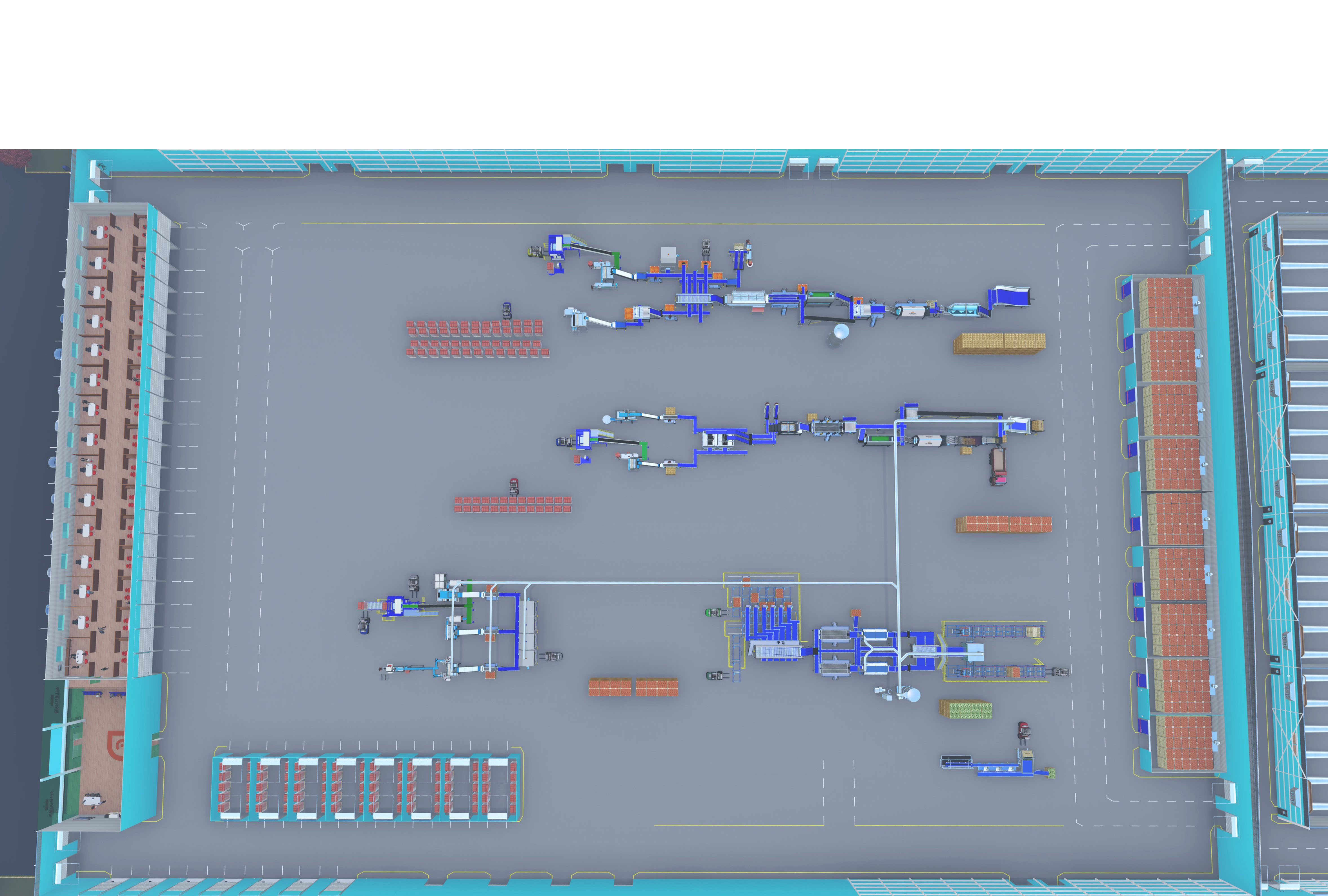

POTATO PROCESSING, STORAGE AND DISPATCH

Industrial potato, table potato and seed potato.

- From tip trailer to boxes

- Wooden boxes 160 x 120 x 123 cm

- Box storage

- Bulk storage

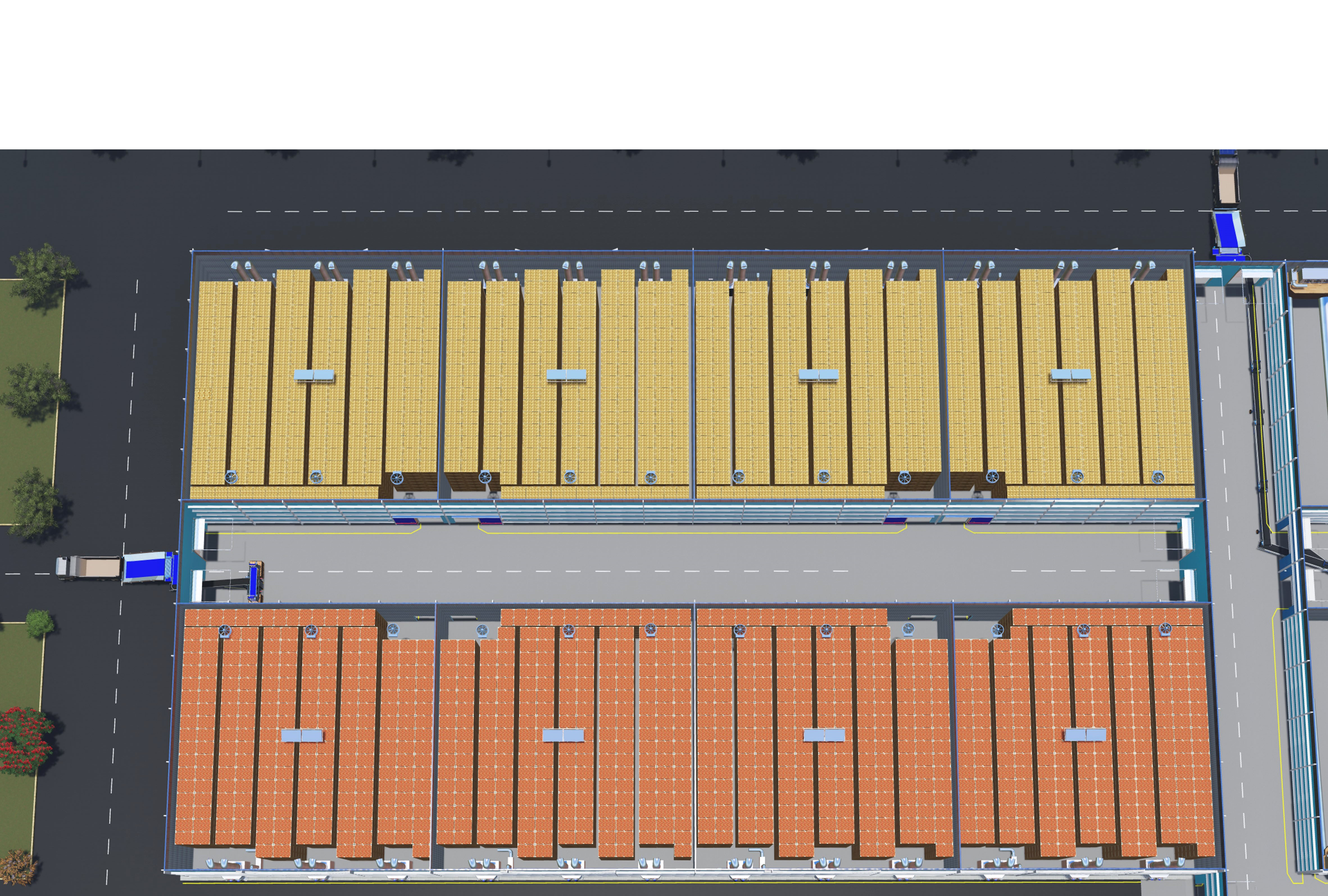

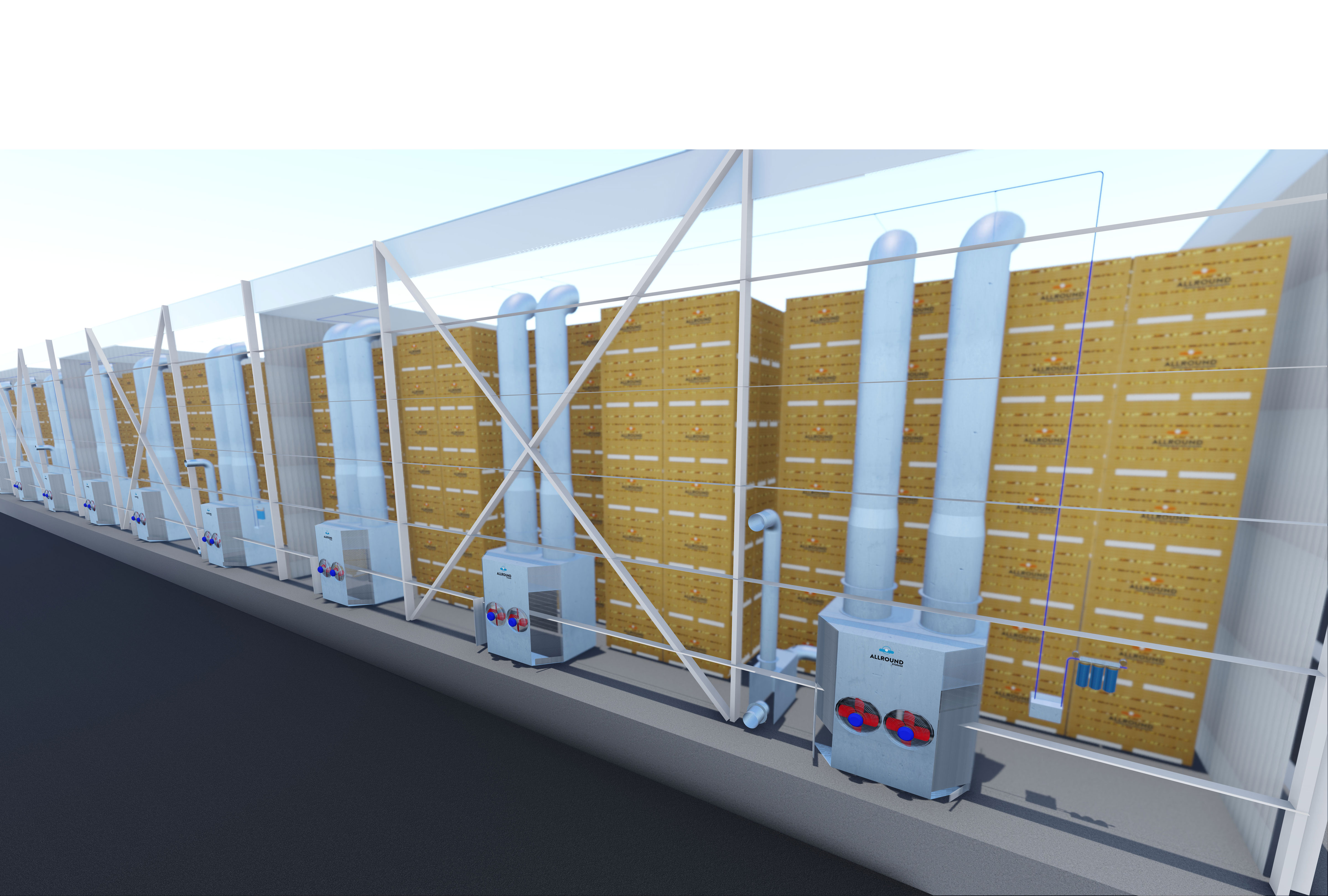

- Storage with cooling machines

- Storage with outside air cooling

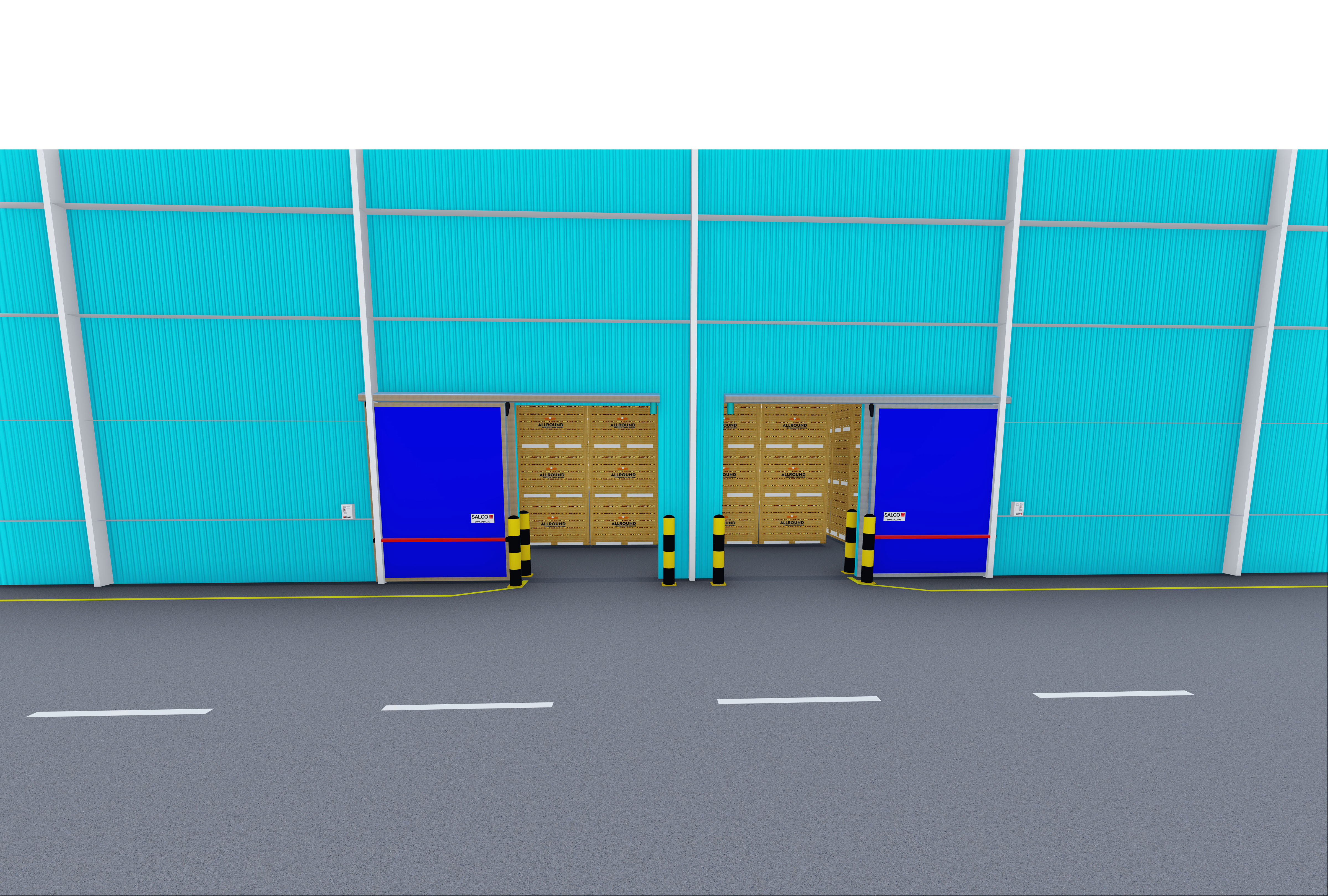

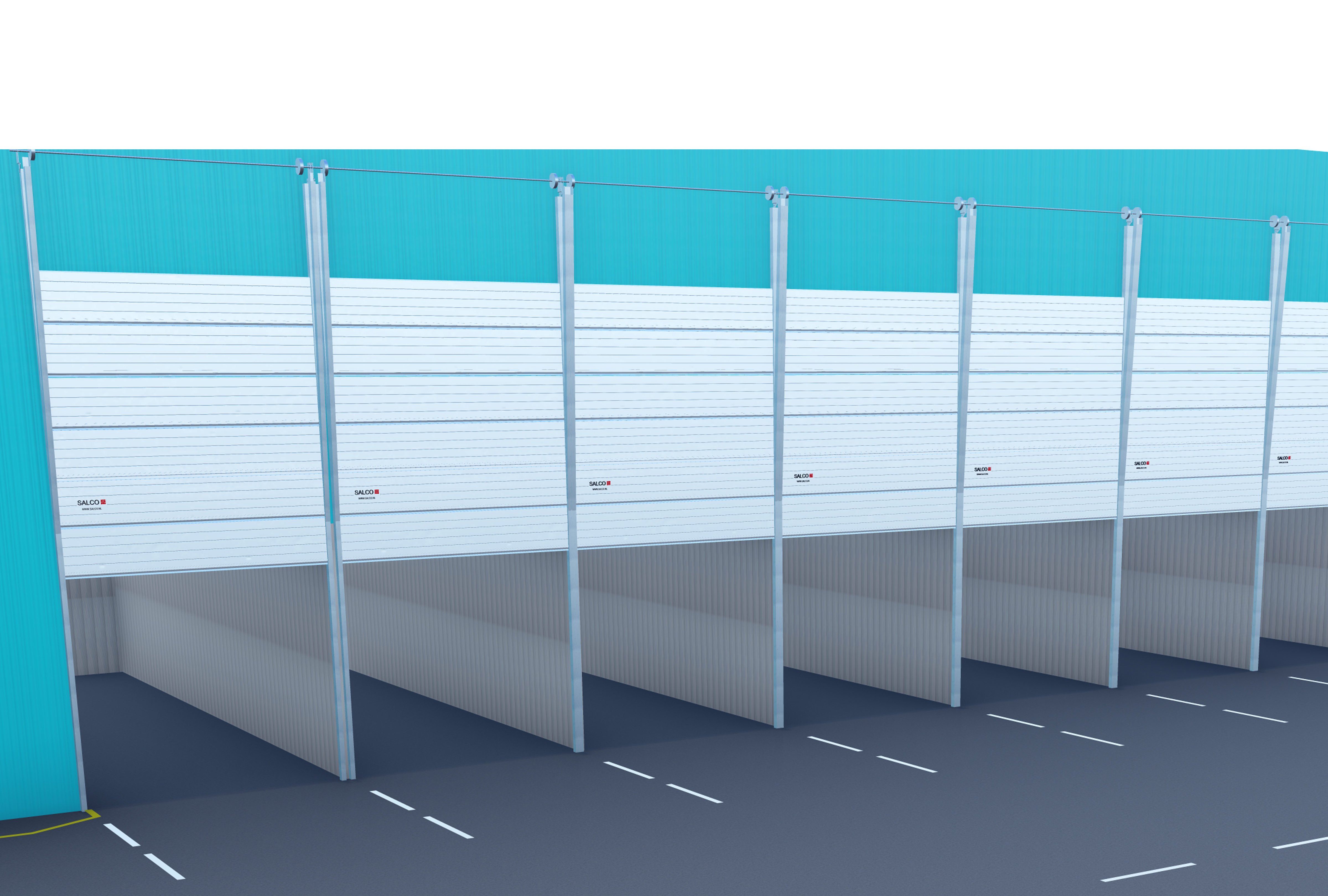

- Salco cooling doors

For a summary of type of each machine see processing line >

Processing:

- Receiving, soil extraction

- Destoning

- Leaf seperating

- Washing with high level, at least 10 cm higher as product.

- Dry cleaning, brushing

- Manual inspection with a roller table so you can see up-side-down

- Grading by square. means on biggest size.

- Buffering, storage hopper

- Central switchboard

Capacity:

- All capacitites are indications are based on experience from the past and depend on soil and product conditions, Allround VP does not guarantee any of them.

- Industrial potatoes ungraded Capacity 40-60 tons per hour

- Table potatoes Capacity 25-30 tons per hour

- Seed potatoes Capacity 20-30 tons per hour

Packaging:

- Weighing 500gr – 25kg

- Packaging 500gr – 50kg

- Fresh and processed

- Export

- Supermarket

- All packaging options

Palletizing:

- Flexible and accurate

- Maximum 15 bags per minute

- Capacity is depending on bag + pallet size and configuration.

- Bag size: 2,5kg – 50kg

CARROT PROCESSING, STORAGE AND DISPATCH

- Way of harvesting direct from field in boxes

- For long term storage with 15% of soil in order to create micro climate.

- With pure sandy soil long term storage very difficult.

- Wooden boxes 160 x 120 x 123

- Storage at >95% humidity and 1-2 degrees.

- Carrots has to been cooled down to 10 degrees as quick as possible. Always cooling machines needed.

- From 10 to 1 cool a half degreed a day

- Salco cooling doors

For a summary of type of each machine see processing line >

- Receiving, soil extraction

- Jacuzzi, in combination with washing machine with very heavy poluted product. Only jacuzzi (without washing machine) relatively clean carrots.

- Leaf seperator

- Washing carrots on low water level, same level as layer of product.

- Dry cleaning, brushing not possible with carrots

- Pre inspection, for particals not suitable for human or animal consumations. Sometimes not needed.

- Chunk grading to get rid of broken carrot, this machine saves about 2 person at manual inspection table

- Polisher for high shiny carrots

- Bypass if polishing not needed or required.

- Manual inspection, only for carrot a flat belt, with roller inspection table carrot might get speed it up.

- Hydrocooler for cooling down carrots fast by spraying ice cold water. Before the carrot is transported or stored. Position of the hydro cooler can be also after grading, for example 2 sizes. (Δ t/°C x Kg product/hour) x 1.36 = (NCC÷1000) kW

- Elevator to grading machine. Possibility to spraying installation for chlorine

- Radial grader, grading on diameter means on smallest size.

- Lenght grader, Needed when several carrots can’t fit in particular sizes of bags.

- Even-flow hopper. To overcome capacity differences between grading washing line and weighing and packaging installation.

- SHB storage hopper/boxtipper combination. To feed the weighing and packaging machines with cubic boxes.

- Central switchboard

Capacity:

- All capacitites are indications are based on experience from the past and depend on soil and product conditions, Allround VP does not guarantee any of them.

- Capacity nantes approx. 15 tons per hour

- Capacity chantenay approx. 15 tons per hour

- Bottle neck, polisher and washing machine approx. 15 ton per hour

Packaging:

- Weighing 500gr – 25kg

- Packaging 500gr – 50kg

- Fresh and processed

- Export

- Supermarket

- All packaging options

Palletizing:

- Flexible and accurate

- Maximum 15 bags per minute

- Capacity is depending on bag + pallet size and configuration.

- Bag size: 2,5 kg – 50kg

ONION PROCESSING, STORAGE AND DISPATCH

Onion, shallots, set onions and garlic

- Bulk storage (hybrid variaties only)

- Box storage

- When needed to be dried with heaters or dryers.

- Wooden boxes 160 x 120 x 123

- Storage at 65% humidity and 2 degrees.

- Salco cooling doors

For a summary of type of each machine see processing line >

Processing:

- Automatic infeed of cubic boxes

- Pre-grader with a radial grader. to 2 sizes to 2 different onion toppers with different sieves. To get a better onion topping result.

- Two elevators

- Manual inspection with a roller table so you can see up-side-down.

- Radial grader, grading on diameter means on smallest size. Also possible with shake grading/square grading. grading on the biggest size

- important for more veriaties. See differents >

- Box filling with vertical belts.

- Automatic box removing system.

- Central switchboard

Capacity:

- All capacitites are indications are based on experience from the past and depend on soil and product conditions, Allround VP does not guarantee any of them.

- Capacity approx. tons per hour

For a summary of type of each machine see packaging line >

Packaging:

- Weighing 500gr – 25kg

- Packaging 500gr – 50kg

- Fresh and processed

- Export

- Supermarket

- All packaging options

Palletizing:

- High speed, versatile and fully automatic.

- Maximum 30 bags per minute

- Capacity is depending on bag + pallet size and configuration.

- Bag size: 2,5 kg – 50kg

- Automatic pallet dispenser

CABBAGE PROCESSING, STORAGE AND DISPATCH

- Brought in in open boxes (mostly in metal boxes)

- Storage at >95% humidity and 1-2 degrees.

- Cabbage has to been cooled down to 10 degrees as quick as possible. Always cooling machines needed.

- From 10 to 1 cool a half degreed a day

- Salco cooling doors

For a summary of type of each machine see processing line >

Processing:

- Box tipper without falling height. Witch automatic dosing system.

- Dosage belt, with detection at the end makes to belt control itself.

- Product belt for unprocessed cabbage. From this belt people takes cabbage for processing and cleaning.

- Electronic eye on product belt makes the belt stop when to product-flow is too big.

- Air pipes on working places. The airpipe blow the leaf of the cabbage wide, which it easy to peel the cabbage.

- Collection waste belt. With optional elevator to box or tip trailer.

- Grading machine works on the principle of dividing belts, the cabbage falls down into four separate compartments.

- Optional: weigher for nett bags of 25kg.

- Central switchboard

Capacity:

- All capacitites are indications are based on experience from the past and depend on soil and product conditions, Allround VP does not guarantee any of them.

- Capacity depending on the weight of the cabbage of 1kg or 3kg. An average of 200 cabbage per our. Saving on labour can rise up to 40%.